An enterprise resource planning (ERP) inventory system provides an integrated solution for managing inventory, operations, and financial planning. It connects different departments to establish an automated flow of data, improving efficiency and collaboration across the business.

This quick guide dives into the concept of ERP inventory management, outlines the benefits and risks, and provides some best practices for implementing an ERP inventory system.

What is ERP inventory management?

ERP inventory management is a comprehensive approach to overseeing a company's inventory levels, orders, and deliveries. It combines various functions like finance, human resources, sales, and inventory into a single system.

Through interdepartmental collaboration, ERP inventory management helps to streamline processes and improve visibility across the entire organisation.

What is an ERP inventory system?

An ERP inventory management system is a type of software that helps businesses manage and integrate the important parts of their operations. It connects inventory management with related functions, such as purchasing and customer management, to enable a unified platform for operations.

Key features of an ERP inventory system

ERP inventory software features vary from system to system. In addition to real-time inventory management, most tools also provide functionality for managing purchase orders, integrating sales, and storing customer information.

Here are some common ERP inventory system features:

- Centralised database: All inventory information is stored and managed in the same digital location, along with other relevant data such as sales orders and invoices.

- Perpetual inventory management: Real-time tracking of inventory levels, orders, sales, and deliveries ensures data in the system is up-to-date and accurate.

- Automation: Manual processes like order processing, invoicing, and reporting are performed automatically to save time and minimise human error.

- Analytics and reporting: ERP inventory systems monitor key insights into inventory performance, sales trends, and customer preferences so you can make smart improvements to your business based on real data.

- Integration capabilities: The system should seamlessly connect with other business software such as CRM, accounting, and eCommerce platforms.

- Scalability: A good ERP inventory system adapts to the growing needs of your business to accommodate new products, locations, and sales channels.

- User access: Controls to manage user permissions, ensuring staff have appropriate access to inventory information.

- Inventory optimisation: Data analysis tools help you forecast sales demand to prevent overstocking and stockouts.

- Procurement: ERP inventory systems connect purchasing and supplier management with stock control to ensure the right goods are ordered at the right time to meet demand.

- Warehouse management: Functionality that helps streamline daily warehouse processes and optimise the layout of your storage facilities.

These features combine to create a powerful tool for businesses to maintain optimal inventory levels, meet customer demand, and make informed decisions.

However, this list is not exhaustive.

Many ERP inventory management solutions will also feature tools for manufacturing, accounting and payroll, CRM, and staff management. When shopping for software, it’s best to consider which features are essential to solving your most dire inefficiencies.

Benefits of ERP inventory management

ERP inventory management systems can lead to significant improvements in inventory accuracy, cost reduction, and operational productivity. It enhances visibility into inventory levels, aids in demand forecasting, and optimises replenishment strategies.

Improved efficiency

ERP systems automate routine processes like order processing, inventory tracking, and payroll management. This reduces the need for manual intervention, decreases errors, and allows employees to focus on more strategic tasks.

With all business data in one place, employees can easily access the information they need, reducing the time spent searching for data across various systems.

Different departments can work seamlessly together enabling employees to collaborate more effectively thanks to integrated processes. For example, sales data automatically updates inventory levels, which informs the purchasing department.

Cost savings

By integrating all functions into a single system, businesses can eliminate redundant processes and systems to minimise operational costs.

Better inventory management helps reduce excess stock and minimise stockouts, leading to cost savings. You can better align inventory levels with actual demand – protecting your cash flow for when you need it most.

Streamlined operations also mean you can do more with less – fewer errors and less manual work result in lower labour costs and higher productivity.

Better decision-making

ERP inventory systems provide real-time data and analytics, allowing leaders to make informed decisions quickly. This can lead to more agile and responsive business strategies.

Advanced reporting tools within ERP systems generate detailed reports that help you understand trends, forecast future demand, and plan resources efficiently. With centralised and accurate data, you can trust the information you use to make critical decisions, reducing the risk of decisions based on faulty or incomplete data.

Scalability

As your business expands, you can begin to integrate additional modules into your ERP system. For example, you might start with finance and inventory management and later add customer relationship management (CRM) or human resources.

ERP inventory systems are also designed to support an increasing number of users. As your team grows, you can add more user accounts without compromising system performance.

Lastly, an effective ERP inventory management solution can manage larger volumes of data as your business transactions increase, ensuring smooth operations without lag or data processing issues.

![]()

How does ERP inventory management work?

ERP inventory management works by integrating all inventory-related processes into a unified system, providing real-time visibility and control over inventory operations.

Let’s break it down by the various workflows and benefits they bring to your business.

1. Centralisation of inventory data

- Process: ERP systems centralise inventory data, providing real-time insights into stock levels, order processing, and supply chain operations.

- Benefit: Ensures consistent and accurate information is available across the organisation, facilitating better decision-making and coordination.

2. Automated inventory tracking

- Process: The system uses barcode scanners, RFID tags, or other automated technologies to streamline the tracking of inventory items.

- Benefit: Maintains precise records of inventory movements, reducing errors and inefficiencies, and enhancing overall accuracy.

3. Stock management and reorder automation

- Process: Provides tools for managing stock levels, setting reorder points, and automating purchase order management.

- Benefit: Eliminates manual processes and human error while maximising efficiency throughout the inventory lifecycle.

4. Demand forecasting and procurement planning

- Process: Powerful tools analyse historical data and market trends to forecast demand.

- Benefit: Aids in planning procurement and production activities to align with expected sales, optimising inventory levels and reducing overstock or stockouts.

5. Reporting and analytics

- Process: The ERP inventory system helps produce invaluable reports that can be viewed and modified on user-friendly dashboards.

- Benefit: Allows you to analyse inventory performance, identify trends, and make informed decisions to improve efficiency and reduce costs.

6. Workflow customisation

- Process: Provides the ability to customise workflows according to specific business processes and unique company needs.

- Benefit: Ensures tasks are managed effectively as the company’s needs evolve, offering flexibility and adaptability.

7. Integrating other business modules

- Process: Integrates seamlessly with other business modules such as finance, sales, production, and distribution.

- Benefit: Ensures comprehensive management of resources, enhancing overall organisational efficiency and effectiveness.

ERP inventory management software

ERP inventory management software is a type of ERP inventory system that focuses on increasing efficiency and lowering the costs of inventory-related processes such as stock control, purchasing, and order management.

Unlike more complex ERP systems, ERP inventory software like Unleashed is an affordable solution for small and medium enterprises that still provides advanced tools for managing, tracking, and optimising your inventory.

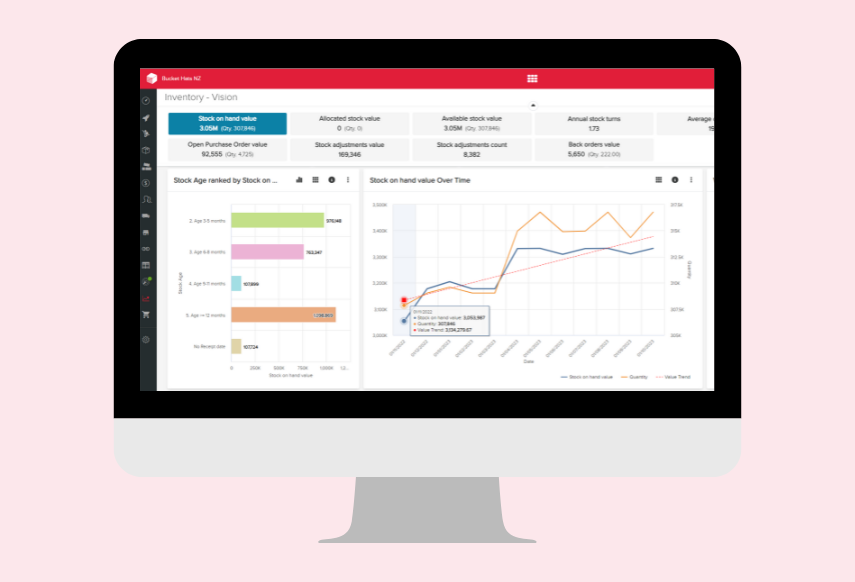

ERP inventory software systems enable real-time tracking of key metrics, including your current stock on hand value.

ERP inventory software systems enable real-time tracking of key metrics, including your current stock on hand value.

Advantages of ERP inventory management software:

- It replaces manual tracking across different platforms with a central system, reducing errors and saving time.

- Streamlines all warehouse operations, including receiving, picking, packing, and shipping, for improved efficiency.

- Provides real-time inventory levels, eliminating the need for annual counts and reducing stock discrepancies.

- Offers tools for forecasting and adjusting inventory levels to meet fluctuating customer demand.

- Enhances the ability to locate and identify inventory, leading to more accurate and timely shipments.

- Reduces the reliance on paper-based processes, which are not secure and difficult to scale across multiple warehouses.

- Assists in managing perishable, fragile, or high-value stock with specialised care and loss-prevention strategies.

- Provides flexibility and real-time data to manage the unpredictable nature of global supply chains.

- Helps in efficiently utilising warehouse space and organising inventory.

Everything you need from an ERP system at a fraction of the price

If you’re struggling to accurately keep track of inventory, ERP inventory management software provides a cost-effective solution that saves you hours and helps optimise your daily workflows.

Unleashed is a cloud-based inventory management software solution for small- and medium-sized businesses. Like an ERP system, Unleashed helps you:

- Manage and update inventory levels as stock moves in and out of your business

- Integrate inventory control with procurement, production, and order management

- Identify key sales trends and monitor inventory performance in real time

- Streamline manual inventory processes with supply chain automation

- Connect seamlessly to your other business systems to synchronise crucial data

Is your company or budget too small to justify spending thousands every month on a complicated ERP system? Try Unleashed for free today or book a demo with our sales team to discover if inventory management software is right for you.

The importance of scalability in ERP inventory software

Scalability in an ERP inventory management system refers to the software’s ability to manage increasing amounts of work, or its potential to be enlarged to accommodate that growth.

An ERP inventory system can scale with your business by providing:

- Cost efficiency: Investing in a scalable ERP system means you don’t have to replace your software as your business grows. It adapts to your needs, making it a cost-effective long-term solution.

- Seamless growth: As your business volume increases, a scalable ERP inventory system ensures that all operations, from inventory to customer service, keep pace without disruption.

- Consistent performance: Scalable systems are designed to maintain performance and efficiency levels, even as demands increase. This means you can avoid slowdowns and continue providing excellent service.

- Futureproofing: A scalable ERP system positions your business for future growth, ensuring you’re always ready to take on new challenges without overhauling your technology stack.

ERP inventory system example

Imagine you have a retail business.

In your initial setup, your business uses an ERP system for managing inventory, sales, and financials.

In the growth phase, your business opens new stores, adds more locations to the ERP system, integrates new modules for online sales and customer loyalty programs, and increases the total number of users.

To support your business expansion the system enables the management of multiple warehouses, diverse suppliers, and an international customer base. This ensures that the business’s operations scale efficiently.

A scalable ERP inventory system is a strategic investment that grows with your business, adapts to increasing demands, and supports new processes as they arise.

This flexibility ensures your business can manage growth smoothly, maintaining efficiency and performance without significant disruptions or additional investment in new software.

Risks of ERP inventory management systems

The initial implementation of an ERP system can be daunting due to the costs, required training, and potential for temporary disruption. While ERP systems offer numerous advantages, they also come with risks.

These risks can vary depending on your software vendor, but common ones include:

- Over-reliance on technology

- Potential data inaccuracies

- Expensive and high-risk implementation and data migration

- Hidden costs to maintain and set up

- Reliance on a single vendor and system

For example, if you are a manufacturer implementing an ERP inventory management system, your immediate challenges might be the high initial costs, extensive training required, and potential temporary disruptions during the transition phase.

For large enterprises, the long-term benefits may justify these challenges.

But for smaller, less complicated organisations, ERP systems may prove to be more trouble – and money – than they’re worth.

ERP inventory system implementation best practices

Successful ERP implementation involves careful planning, clear goal setting, thorough testing, and ongoing support. It's crucial to ensure that the system aligns with the business's specific needs and that staff are adequately trained to use it effectively.

Here are 10 best practices for implementing an ERP inventory system:

- Assess organisational needs: Clearly define and document your inventory management requirements before selecting an ERP system.

- Select the right ERP system: Choose an ERP solution that aligns with your business processes, scalability needs, and industry requirements.

- Develop a detailed implementation plan: Create a comprehensive project plan that includes timelines, milestones, budgets, and responsibilities.

- Engage stakeholders early: Involve key stakeholders from different departments to ensure the system meets diverse needs and gains widespread support.

- Data clean-up and migration: Ensure your existing inventory data is accurate and clean before migrating it to the new ERP system.

- Customise thoughtfully: Minimise customisations to reduce complexity and potential future issues. You should only customise when it is necessary to meet critical business needs.

- Thorough training: Provide extensive training for all users to ensure they are comfortable with the new system and understand its functionalities.

- Assess extensively: Perform rigorous testing, including unit tests, system tests, and user acceptance tests, to identify and resolve issues before going live.

- Change management: Develop a change management strategy to manage the transition smoothly and address any resistance from employees.

- Monitor and evaluate: After implementation, continuously monitor the system’s performance and gather feedback to make necessary improvements.