The procurement processes you implement directly impact how efficiently the business operates. When you order the right goods and services at the right time, profits bloom and cash flow will remain stable.

Conversely, the consequences can be disastrous if procurement lacks the right structure or planning.

This guide will teach you the basics of procurement, break down the most important procurement processes you need to know, and explore a few tactics you can use to optimise procurement for the future. Let’s dive right in.

What is a procurement process?

Procurement processes are the workflows or steps a business implements to ensure effective purchasing of goods and services related to the sale of physical products. Common examples of these processes include vendor sourcing, supplier management, and purchase order management.

Strategy is extremely important in the procurement process. The influx of goods into a business directly affects customer satisfaction. The timing, cost, and reliability of purchasing activities also largely determine how profitable your company operates at any given time.

Procurement vs purchasing

Purchasing is one of the core processes in procurement. It’s largely concerned with raising purchase orders, receiving goods, and issuing invoices. However, the procurement process encapsulates far more than just the purchasing of goods and services.

Understanding the procurement process flow

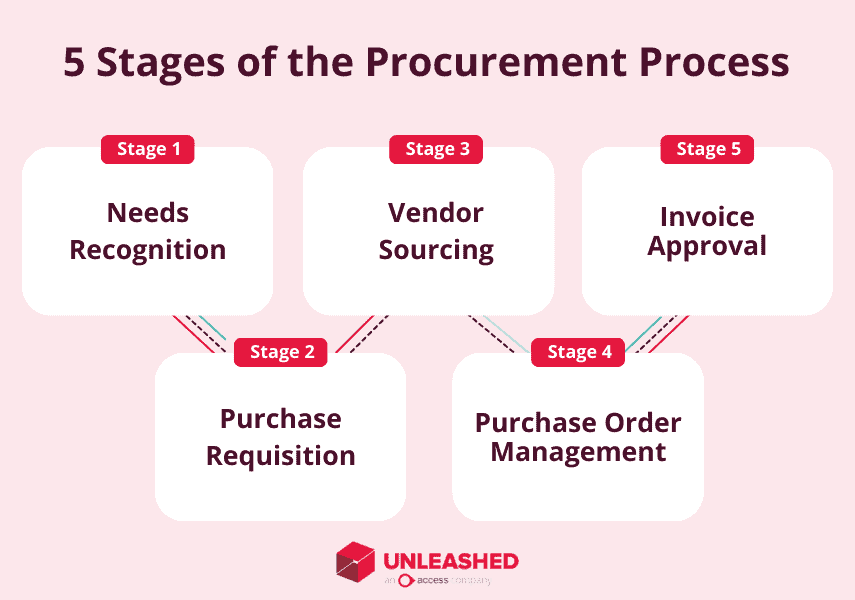

Not every procurement process follows the same steps. However, the majority can be dissected into a system known as the procurement process flow.

It involves five key stages:

- Needs recognition: Using strategic planning, budgeting, and forecasting to identify the goods and services required by a business.

- Purchase requisition: Requisitioning the needed goods and services to gain approval for purchasing.

- Vendor sourcing: Researching, evaluating, and choosing the best suppliers for your requirements.

- Purchasing management: Creating and distributing purchase orders, receiving and confirming goods and services, and inventory management.

- Invoice approval: Confirming invoices, approving payments, and keeping a record of all outgoing transactions related to the business.

Next, we’ll break down some of the key types of procurement processes that involve actioning the above activities.

7 common types of procurement processes

The procurement processes you implement in your organisation may vary depending on current needs, budget, and resources. The following are examples of common procurement workflows to consider.

1. Direct and indirect procurement

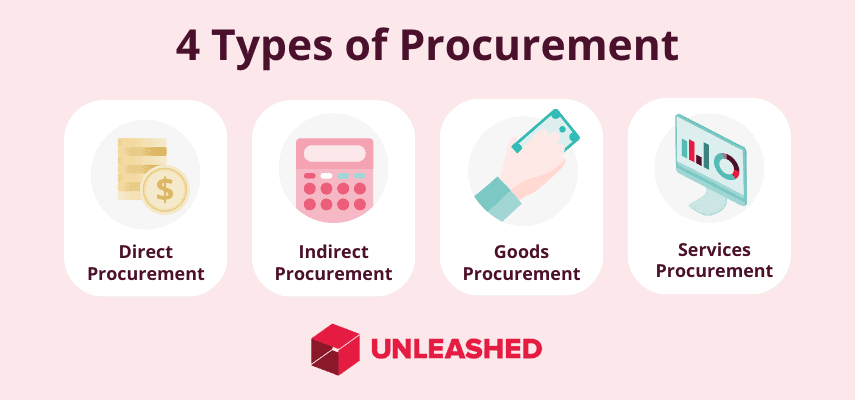

There are two main categories for procurement processes: direct and indirect.

Here’s a quick recap of how they work in modern business:

- Direct procurement: The sourcing of materials, components, products, and services that will be directly incorporated into the goods you sell – everything that goes through to the end customer. When calculating costs, these qualify as direct costs.

- Indirect procurement: Everything that is essential to the manufacturing process but is not directly incorporated into your final products. Some examples include packaging; maintenance, repair, and operating (MRO) supplies; certain professional services (like cleaners or IT); and your utilities bills. In accounting, these would qualify as indirect costs.

In simpler terms, direct procurement relates to purchases that contribute to a specific product’s outcome, while indirect procurement relates to purchases that help keep your operations efficient and functional.

2. Procure to pay (P2P)

The procure-to-pay (P2P) cycle is a strategy that involves streamlining, automating, and integrating various links within a supply chain to enhance procurement efficiency.

The key steps involved in the P2P cycle include:

- Needs identification and forecasting

- Requisition

- Approval

- Supplier management (including sourcing)

- Requests for quotes, proposals, and tenders

- Negotiation

- Order fulfilment

- PO management

- Receiving

- Invoicing and payment

- Record keeping, data collection, and reporting

- Continuous improvement

The P2P procurement process allows purchase managers, accounting teams, strategic leaders, and operators to share the same workflows and data – resulting in an end-to-end procurement system.

3. eProcurement

Electronic procurement, also known as eProcurement, takes traditional procurement processes to the cloud. Where once your company may have used clipboards, spreadsheets, phone calls and meetings to manage procurement, eProcurement digitises and automates your processes.

Key benefits of eProcurement:

- Make digital orders through dedicated procurement systems

- Manage suppliers in a central dashboard

- Automate menial tasks such as purchase order creation and invoice reconciliation

- Improve communication through online collaborative tools

- Gain better insights by collecting analytical data and tracking performance

To build an end-to-end electronic procurement system, you need to invest in digital systems. These may include one or more of the following: procurement software, inventory software, accounting software, or an ERP system.

4. Tender procurement process

The tender procurement process, also known as tendering, is a process whereby one company invites potential suppliers to submit their interest in providing the required goods or services. This invitation is called a Request for Tender (RFT).

Suppliers then submit the tender document in response. In the manufacturing process, for example, an organisation may place an RFT for new machinery or vital production assets.

The tender process can be used in a few different ways, including:

- Requesting quotes and offers

- Requesting proposals

- Requesting information

- Requesting an expression of interest

You can also restrict who you invite to tender. Types of tendering include:

- Open tender: Anyone relevant can submit their tender, allowing you to find the best price and quality on the broader market.

- Closed tender: Only select suppliers can bid. Also known as selective or restricted tendering.

- Innovation partnership: Where the required product or service doesn’t exist, you invite suppliers to invent it for you.

5. Consignment inventory

Consignment inventory is a procurement strategy wherein a supplier provides their goods without charge. The supplier maintains ownership of these goods until you decide to sell them (or use them during production). Consignment inventory is a great way to access new products at a reduced cost and reduced risk.

6. Blanket purchase agreements (BPA)

Blanket purchase agreements (BPA), also known as blanket purchase orders or standing purchase orders, are long-term purchasing frameworks that lay out which goods or services a supplier will provide your business, along with the price and expected delivery time.

Agreeing to a BPA can help cut administrative costs during procurement because it adds certainty; no more sourcing or tendering, plus a more consistent supply chain.

The risk of BPAs is that they lock you in with a particular supplier, meaning you may not be able to access better alternatives if the market changes, your customers demand something different, or you want to change how your business operates.

Common components of a BPA:

- Duration of the contract

- Established price of goods

- Specific quantities (if relevant)

- Agreed-on flexibility on delivery dates and quantities

- Applicable volume discounts

7. Group purchasing organisations (GPO)

Group purchasing organisations (GPO) are like collective-bargaining entities. They’re typically membership-based, utilising the combined buying power of their member organisations to gain more favourable arrangements with suppliers.

In a market governed largely by supply and demand, it can be tricky for smaller organisations to gain these favourable terms on their own. By pooling resources, you can aggregate the demand for materials, equipment, and services – allowing for cost reductions, access to a higher tier of supplier, improved operational efficiency, and the mitigation of risk.

How to choose the right procurement strategies for your business

We can’t tell you which procurement process will be right for your organisation, but we can provide a list of considerations to help you come to the decision yourself.

While comparing procurement strategies, consider:

- The nature of your product: The materials required, the complexity of getting goods onto shelves, customer customisation options, and shifting demand.

- Quality requirements: Your expectations of product and packaging quality, as well as what your customers are expecting.

- Budget: Available cash flow for investing in procurement.

- Risk appetite: Tolerance for inventory and supply chain risks.

Additional factors to consider:

- Expected business growth in the coming 12 months

- Predicted changes to your market, including customer demand

- The complexity of your supply chain

- Your existing business relationships

Remember, you don’t have to go all out straight away. If you’re ever unsure, run a pilot programme first to test a method or a supplier, then slowly scale up or switch strategies based on the results.

6 ways to optimise your procurement processes

Once you’ve established the procurement processes that are right for your business, you can continue building on those efficiency gains with small tweaks over time. Here are some optimisation strategies you can use.

1. Get clear on your needs and goals

All process improvement starts with setting clear goals. It’s hard to know where to go next if you don’t know where the end destination is. Talk to your team about what they need and what will make their lives easier, and work towards establishing a clear, overarching organisational goal.

Establish key performance indicators for implementing and running each procurement process to track progress over time.

2. Automate your repetitive tasks

Automation can make your organisation significantly more efficient.

Automated software solutions aren’t designed to replace humans, but rather to handle the day-to-day menial repetition so that staff can focus more on value-adding activities, complex or creative problem-solving, relationship management, and strategy.

Examples of automation in procurement:

- The automatic creation of purchase orders at designated reorder points.

- Submitting paperwork to the relevant people and handling their responses.

- Adding financial information to the books.

- Updating key stakeholders in real time about the current state of pending orders.

3. Focus on your people

There’s little point in having good procurement processes if you can’t rely on the team members charged with carrying them out. Make sure your staff have all the tools and time they need to perform their jobs effectively.

More importantly, ensure they feel like they have a voice when it comes to implementing any changes to their ways of working. These are the people who best know what works and what doesn’t when it comes to procurement processes – listen to their advice and if it makes sense, take it onboard.

4. Build good relationships with suppliers

While you can automate a lot of the supply chain management process, a healthy business relationship requires a human touch.

Integrate your system with your suppliers’ system to share important data and streamline the purchasing process. This can also add much-needed visibility across inventory availability and potential disruptions. Audit your communication tools and processes to make sure you’re communicating as frequently and effectively as required.

If you’ve got a problem which needs to be solved, consider collaborating with your suppliers to create a solution which works for both parties. Always stick to your agreements and bargain in good faith.

5. Improve inventory visibility

Better inventory management can help you understand your procurement needs. Real-time insight into your stock levels enables you to reorder at the right time, in optimal quantities, to prevent cash flow problems and stockouts. Real-time inventory data can also improve your ability to analyse business performance and make the best decisions moving forward.

- Would you like to boost stock visibility and reduce your inventory costs? Take a peek at our cloud-based inventory management solution today!

6. Establish a cycle of continuous improvement

Get into a cycle of continuous improvement – that is to say, establish a system that ensures you are constantly reviewing and enhancing your procurement processes – to ensure business growth and efficiency never stagnate or decline.