Without the right inventory management solutions in place, it’s almost impossible to maintain optimal stock levels, minimise costs, and improve overall efficiency – all of which are essential to ongoing business success.

Keep reading to uncover the risks and challenges of inventory management, learn about the types of solutions available, and discover some of the most effective inventory management strategies in modern business.

What are inventory management solutions?

Inventory management solutions are the systems and processes designed to effectively oversee the entire lifecycle of your business's inventory, from procurement and storage to distribution and sales. They include all software, hardware, or third-party services designed to facilitate more efficient inventory management practices.

We’ll explore the most popular and helpful inventory management solutions shortly.

First, let’s dive into some of the problems they help to solve.

7 major inventory management risks and challenges

Inventory management, while essential for efficient business operations, can be a major challenge. When done poorly, your company’s profitability will suffer – and consequently, so will your customers and staff.

Here’s a quick look at some of the key risks associated with inventory management.

1. Overstocking and stockouts

Maintaining the optimal inventory levels is a struggle most retailers and B2B firms are familiar with. According to Zebra’s Retail Vision Study, reducing stock-outs and overstocks can lower inventory costs by 10%.

Overstocking occurs when a business holds excessive inventory above what is demanded by customers. It ties up precious capital, leads to extra storage costs, and may result in the product becoming outdated before it can be sold.

On the flip side, inadequate inventory levels can also lead to stockouts. That’s where products are not available when customers want to purchase them. The consequence of stockouts can be lost sales, dissatisfied customers, and damage to the business’s brand reputation.

2. Accurately forecasting customer demand

Accurately predicting future demand for products can be a significant challenge for inventory managers. Rapid changes in consumer needs can catch businesses off guard. Inventory that was once in high demand may become obsolete, requiring agile adjustments to prevent excess stock.

Seasonality and fluctuations in market trends can also make it difficult to forecast demand correctly. Managing inventory effectively during peak seasons and avoiding excess stock during off-peak times requires a careful balance.

3. Inventory discrepancies and obsolete stock

Inventory shrinkage (caused by theft, damage, or other forms of loss) requires careful risk management. It poses unique inventory accounting challenges – and can be a sign of inefficiencies in your processes.

Products that become outdated also pose a risk to inventory management. This can occur due to changes in technology, market trends, or regulatory requirements. Managing shrinkage and obsolete inventory is challenging and can lead to financial losses if not addressed promptly.

4. Supply chain management

Managing inventory becomes challenging in complex supply chains with multiple suppliers and distribution channels. Coordinating the movement of goods, dealing with lead times, and ensuring timely replenishment require robust supply chain management practices.

External factors such as natural disasters, political instability, or global events can also disrupt the supply chain. This may impact the restocking of inventory and lead to stockouts or increased holding costs.

For these reasons, maintaining strong relationships with your suppliers is crucial.

5. Outdated technology and inaccurate data

Manual errors in order processing, picking, packing, or shipping can result in inventory discrepancies. Businesses may end up ordering the wrong quantities or making incorrect assumptions about demand, leading to financial losses and operational inefficiencies.

However, automated systems come with risks as well.

Reliance on technology – such as barcode scanners, Radio Frequency Identification (RFID) systems, or inventory management software – increases the risk of technical failures. System glitches, downtime, and cyberattacks can disrupt the normal functioning of inventory management solutions, impacting the accuracy and reliability of your data.

6. Regulatory compliance

Compliance with regulations related to inventory management such as safety standards, environmental regulations, or industry-specific requirements, is crucial. Failure to comply with these regulations can lead to legal consequences and damage to the company's reputation.

7. Omnichannel order management

The rise of eCommerce and the demand for omnichannel experiences mean that businesses must manage inventory across various platforms, both online and offline. Coordinating inventory levels and order fulfilment in this diverse landscape can be extremely complex.

Additionally, the synchronisation of sales and inventory data between different channels poses implementation risks – and can lead to stock discrepancies if not properly set up.

Types of inventory management solutions

Inventory management solutions can be divided into three categories:

-

Automated solutions

-

Manual solutions

-

Third-party solutions

Each of these types of inventory management solutions has its place in an effective stock control workflow. Here are some examples to consider for your business.

Automated inventory management solutions

Automated inventory management software leverage technology to streamline the tracking and control of a business's inventory.

These systems use advanced tools such as barcode scanners, RFID technology, and automated data entry to reduce manual errors and improve efficiency.

By automating repeatable tasks, businesses can enhance accuracy and save valuable time.

Examples of automated inventory management solutions:

-

Inventory control software: Inventory management software is a digital tool designed to help businesses control their inventory effectively. It provides a centralised platform for tracking stock levels, managing product information, and handling order processes.

-

Warehouse management software: Warehouse management software focuses on optimising the various aspects of warehouse operations and provides tools for improving inventory visibility, space utilisation, and order processing automation.

-

Warehouse robotics: Warehouse robotics involves the use of automated machines and robots to perform tasks within a warehouse or distribution centre. These robots can handle activities like picking, packing, and transporting goods, contributing to increased performance and reduced labour costs.

-

Inventory forecasting software: Inventory forecasting software uses algorithms and data analysis to predict future demand for products. This technology helps you make informed decisions about inventory levels, ensuring they meet customer needs without overstocking.

-

ERP software: Enterprise Resource Planning (ERP) software is a solution that integrates various business processes, including inventory and supply chain management. In the context of inventory management, ERP systems offer a holistic view of the entire supply chain, enabling businesses to make strategic decisions based on real-time data.

These solutions often integrate with other business systems, providing real-time insights and enabling proactive decision-making to maintain optimal stock levels.

Manual inventory management solutions

Manual inventory management solutions are traditional (non-digital) methods for tracking and controlling your business's inventory.

While manual methods are more labour-intensive and prone to human errors, some businesses – especially smaller ones with simpler operations – may still rely on manual inventory management systems.

Examples of manual inventory management solutions:

-

Inventory management facilities: Inventory management facilities encompass the physical spaces where businesses store and handle their inventory. These can range from traditional warehouses to roboticised fulfilment centres.

-

Warehouse tools and equipment: Warehouse tools and equipment are essential elements in the daily operations of inventory management facilities. Some examples include forklifts, pallet jacks, and conveyor systems that aid in the storage and retrieval of goods.

-

Inventory management staff: Inventory management staff refers to the individuals responsible for overseeing various aspects of inventory control, including inventory managers, stock clerks, and warehouse supervisors.

Third-party inventory management solutions

Third-party inventory management solutions involve outsourcing the management of your business's inventory to external service providers. These providers specialise in handling various aspects of inventory control, such as order fulfilment and distribution.

By leveraging third-party services, businesses can often benefit from cost savings, improved scalability, and increased flexibility.

Examples of third-party inventory management solutions:

-

3PL inventory management: Third-party logistics (3PL) inventory management refers to outsourcing logistics and supply chain activities to external service providers. A 3PL provider takes on responsibilities such as warehousing, transportation, and order fulfilment. Businesses partnering with 3PL providers can benefit from shared resources, expertise, and a more streamlined supply chain.

-

4PL inventory management: Fourth-party logistics (4PL) inventory management represents an elevated level of outsourcing beyond 3PL. In a 4PL arrangement, a central provider manages and oversees the entire supply chain on behalf of the business. This includes coordinating multiple 3PL providers, optimising processes, and providing strategic insights. 4PL providers often leverage advanced technologies and analytics to offer end-to-end supply chain visibility.

-

Dropshipping: Dropshipping inventory management is a business model where retailers sell products without stocking them physically. When a customer places an order, the retailer purchases the item from a third party (usually a wholesaler or manufacturer) who then ships the product directly to the customer. Dropshipping eliminates the need for businesses to manage their own inventory or warehouse space.

Third-party inventory management solutions are particularly popular for eCommerce businesses that want to focus on core activities while entrusting the complexities of inventory management to specialised service providers.

Inventory management software solutions

Inventory management software solutions are digital tools designed to streamline the tracking, monitoring, and control of a business's inventory. These software applications offer a centralised platform where businesses can manage product information, track stock levels, and automate various aspects of the inventory lifecycle.

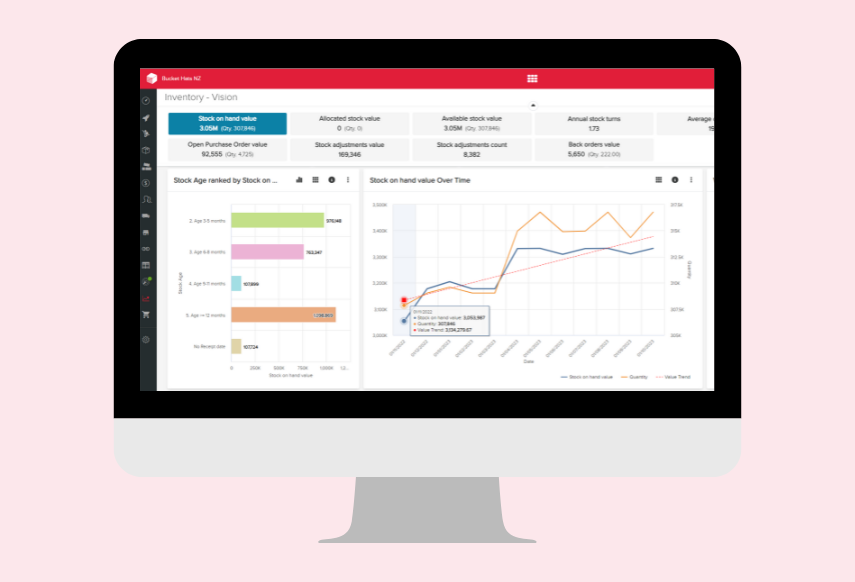

Perpetual inventory software systems enable real-time tracking of key metrics, including your current stock on hand value.

Perpetual inventory software systems enable real-time tracking of key metrics, including your current stock on hand value.

Common inventory management software features:

-

Real-time reporting

-

Automated inventory tracking

-

Purchase order management

-

Barcode scanning

-

Demand forecasting

-

Production planning

-

Multichannel sales order management

-

Integration with other business systems

Inventory management software solutions play a crucial role in reducing manual errors and optimising operational efficiency by providing businesses with the tools they need to make the right decisions.

Vendor-managed inventory solutions

Vendor Managed Inventory (VMI) solutions are collaborative approaches to inventory management where the vendor takes an active role in monitoring and replenishing a customer's inventory.

In a VMI system, the vendor receives access to real-time data on the customer's stock levels and – based on agreed-upon criteria – manages the replenishment process. This collaborative approach helps businesses maintain optimal inventory levels, reduce stockouts, and streamline the supply chain.

VMI solutions often rely on electronic data interchange (EDI) and other technologies to facilitate seamless communication between the customer and the vendor.

12 effective inventory management strategies

Effective inventory management is crucial for businesses to optimise their operations and meet customer demands. Adopting a combination of these strategies – tailored to the specific needs of the business – can contribute to reduced costs and improved customer satisfaction.

Here are twelve of the most effective inventory management strategies.

1. ABC analysis

Implement ABC analysis to categorise items based on their importance. Classify products into three categories: A for high-value items, B for moderate, and C for low. This helps prioritise focus on critical items and allocate resources efficiently.

2. Demand forecasting

Utilise accurate demand forecasting methods to predict future demand. Analysing historical sales data, market trends, and seasonal variations can assist in making informed decisions regarding stock levels and reorder points.

3. Safety stock

Maintain a safety stock level to buffer against unexpected demand spikes, supply chain disruptions, or delays. This safety stock acts as a cushion to prevent stockouts and ensures that products are available when needed.

4. Just-in-Time (JIT) inventory

Consider a just-in-time inventory strategy to minimise holding costs. With JIT, products are ordered and received just in time for production or customer demand, reducing excess inventory and associated carrying costs.

5. Product bundling

Strategic product bundling can help to manage slow-moving items. Combining slow-moving products with faster-moving ones in bundles can help clear out inventory and promote sales.

6. Economic Order Quantity (EOQ)

Calculate the economic order quantity (EOQ) to determine the optimal order quantity that minimises total inventory costs, including ordering and holding costs. This strategy helps find the right balance between ordering in bulk to reduce costs and avoiding excess inventory.

7. Vendor-managed inventory (VMI)

Collaborate with suppliers through Vendor Managed Inventory (VMI) to allow suppliers to monitor and manage inventory levels. This promotes better coordination, reduces stockouts, and streamlines the replenishment process.

8. Audits and cycle counts

Conduct regular inventory audits and cycle counts to verify the accuracy of stock levels. This helps identify discrepancies, reduce errors, and maintain reliable inventory data for decision-making.

9. Technology integration

Leverage inventory management software and technology solutions. Automated systems, such as barcoding, RFID, and advanced software platforms, improve accuracy, streamline processes, and provide real-time insights into inventory levels and movements.

10. Collaboration

Foster collaboration between different departments, such as sales, marketing, and operations. Sharing information on promotions, product launches, and changes in demand patterns helps align inventory management with overall business strategies.

11. Supplier relationships

Cultivate strong relationships with suppliers. Open communication, clear expectations, and collaborative planning can lead to better terms, reduced lead times, and improved reliability in the supply chain.

12. Continuous monitoring and improvement

Implement a culture of continuous monitoring and improvement. Regularly assess and adjust inventory management strategies based on changing market conditions, customer preferences, and evolving business needs.