A production schedule can help you bring down manufacturing costs and maximise efficiency during the production process. Effective production scheduling can mean the difference between a happy customer and a job that was cancelled because it wasn’t completed on time.

Keep reading to learn what a production schedule is, how to create one, and the actionable tips that’ll help you maximise success and improve productivity in your production scheduling process.

What is a production schedule?

A production schedule is a project plan detailing the scheduled timeline for goods to be manufactured. It may contain key information about the items being produced and the manufacturing process itself, including any raw materials, labour, and equipment – along with the scheduled dates for executing each stage of the production process.

Simply put, a production schedule acts as a calendar that shows each step required to produce a finished good.

Production schedules help manufacturers avoid stockouts and bring costs down while increasing manufacturing efficiency. For the customer, production schedules aim to shorten lead times and improve the quality of goods produced. This means better products, faster order fulfilment, and happier customers.

The role of a production scheduler

A production scheduler is the person who is responsible for creating your production schedule. They might be the production manager involved in all tasks related to production, or a dedicated person employed solely for this task.

The role of a production scheduler includes:

- Analysing your manufacturing capacities

- Identifying deadlines and detailing how you’ll meet them

- Consulting the production plan and preparing contingencies within the schedule to mitigate any challenges

- Liaising with relevant stakeholders to ensure the right expertise has been taken into account

- Creating processes that will improve manufacturing efficiency and reduce costs

- Producing the production schedule document

It is also the responsibility of the production scheduler to make any necessary adjustments to the schedule once production has begun. This is an important task, as unforeseen disruptions may force a complete rescheduling of certain processes.

Production scheduling vs production planning

Production scheduling is the process of determining when products will be manufactured and setting a timeline for production. Its goal is to ensure goods are manufactured with maximum efficiency, on time and within budget.

Production planning precedes production scheduling. It is the process of determining future demand for products, how those products will be manufactured to meet that demand, and the manufacturing metrics that will measure success. Production planning also involves mapping out the required materials, labour, and equipment for a future production job.

Here’s the difference between a production plan and a production schedule:

- A production plan is a document containing a top-down view of manufacturing processes, requirements, and forecasted demand for a product.

- A production schedule is a document that tells manufacturers which goods need to be produced, when they need to be produced, and the production methods.

You can think of a production plan as the ingredients list for a product. The production schedule acts as the recipe for building that product.

Why is a manufacturing production schedule important?

A production schedule helps significantly in reducing manufacturing costs and improving the efficiency of your manufacturing inventory management.

But that’s not all.

A production schedule also helps to:

- Prevent stockouts – Forecasting demand and planning contingencies for disruptions to production means you’re better able to maintain production throughout the year.

- Improve efficiency – A production schedule can improve productivity by putting steps in place to mitigate any risks or bottlenecks identified during the production planning process.

- Identify opportunities – Addressing inefficiencies also provides the data you need to find opportunities for optimisation.

- Increase visibility – A production schedule creates a paper trail for your manufacturing activities. This facilitates better communication and ensures clarity around project requirements and timelines.

- Manage production costs – By increasing manufacturing process efficiencies, a production schedule simultaneously helps to minimise the cost of inventory and production.

To summarise, a manufacturing schedule is important because it ensures your business is operating at maximum efficiency while keeping costs as low as possible. The reduced production costs directly translate into wider profit margins for your products.

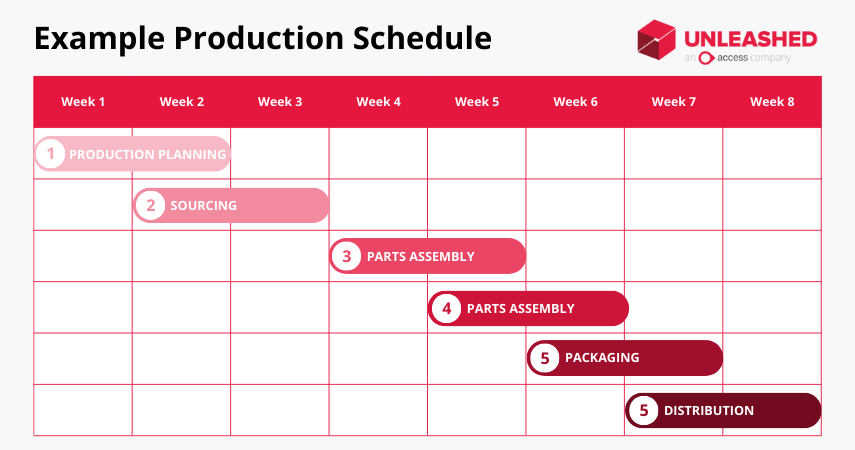

Production schedule example

Production schedules can be highly complex documents produced by manufacturing software that go into detail about each stage of production, or they can be simple spreadsheets that just list out the start times and deadlines for each process.

The production schedule example below demonstrates how the latter might look:

As you can see, specific cells from each row have been blocked out. These cells reflect the period during which each stage of production is expected to take place.

Creating a production schedule

We can break down the process of creating a production schedule into five elements:

- Production planning

- Routing

- Production scheduling

- Dispatch and execution

- Maintenance

Here’s what to expect from each stage.

1. Production planning

Production planning is the process of developing a strategy for achieving your manufacturing goals. It can also include determining what those goals should be.

The purpose of production planning is to create a document – the production plan – that describes which goods are to be manufactured, how you’ll manufacture them, and any resources such as raw materials or labour required to produce those goods.

The information captured during the production planning stage may be communicated via the production schedule or in a separate document.

2. Routing

Routing refers to the path taken by raw materials and components as they pass through the production line and are eventually used to create a finished good.

When it comes to creating a production schedule, routing optimisation is how you make your production process efficient. It involves mapping out each step required to build a product, identifying the optimal sequence of operations, and looking for ways to improve efficiency within each step.

3. Production scheduling

Production scheduling is when you use the information you’ve gathered in the earlier steps to create a calendar-format document – your production schedule.

The production scheduling process focuses on creating 1–3 types of schedules:

- Master production schedule: A planned timeline of the entire production process.

- Manufacturing production schedule: A planned timeline for the conversion of raw materials into a finished product.

- Retail operations schedule: A planned timeline for transporting finished goods to your store.

When each schedule is ready, it should be shared with the relevant stakeholders so they may review it and offer any feedback.

Once approved by the necessary parties, the production schedule should be communicated to all employees who will be involved in the manufacturing process.

4. Dispatch

Dispatching is the process of assigning people to tasks. Now that you know what work needs to be done and when it needs to be done, communicate with your team to determine how they will manage their roles. This can include breaking down any manufacturing methods, parts-picking strategies, and processes for moving goods along each stage of the production line.

5. Maintenance

Once you’re confident in your approach, it’s time to execute the tasks in your production schedule.

Because things can often go awry in manufacturing, you’ll need to keep an eye on the progress of your production activities. There’s a good chance that your production schedule will need some adjusting: Customer demand could change, supply chain disruptions could slow down production, or equipment failure may prevent goods from being produced on time.

Update the production schedule to account for unexpected interruptions as necessary. Make sure your staff are informed of any changes made to the original schedule.

Production scheduling best practices

Are you ready to dive into the production scheduling process for your next project? Here are some actionable tips and production scheduling best practices to help you along.

1. Stay flexible

Plans often change, so a production schedule needs to be dynamic. When you create your production schedule, allow flexibility for changes to dates, tasks, and resources. Make a plan around how you’ll communicate any changes to the original production schedule to your staff.

2. Implement production scheduling software

Spreadsheets are helpful, but they can be limiting. If production scheduling is a regular activity in your business, you may benefit from investing in specialised production management software. Cloud-based tools can automate repetitive production scheduling tasks, allowing you to complete more tasks in less time.

3. Prioritise based on need

You might be tempted to prioritise tasks based on their deadline or how demanding a certain customer is. However, this strategy can be risky. Consider the master production schedule and each task’s requirements and focus on those with the highest need or highest risk first.

4. Optimise your inventory management

Improve your inventory management processes to boost inventory accuracy and prevent stockouts that could affect production times. When your goods are tracked and managed efficiently, you’ll be in a better position to forecast inventory requirements and adjust your purchasing processes accordingly.

5. Don’t forget equipment maintenance

The last thing you need is for something to unexpectedly break while you’re in full swing. Equipment maintenance can slow down processes, feeling like a chore you want to avoid rather than encourage. But preventative maintenance can mean the difference between a small amount of regularly scheduled downtime and a lot of downtime spent fixing or replacing broken equipment.

Production scheduling software

Production scheduling software refers to digital tools designed to streamline the process of creating, updating, and distributing a production schedule.

Many production planning and production scheduling software come as a complete package. This is good news for small businesses, as it means you’ll have fewer licences to purchase. For businesses with large or complex production processes, production scheduling can also be found as a module inside ERP and MRP software.

In addition to these options, there are other software tools that are useful for specific stages in the production scheduling process.

These include:

- Demand forecasting software – to help you accurately predict future demand for specific products so you can plan and schedule production activities accordingly.

- Inventory management software – to help you optimise your inventory levels so that there is always sufficient stock available to meet your production needs.

- Procurement and purchasing software – to facilitate better supplier sourcing and communications, shorten raw materials lead times, and reduce the risk of supply chain disruptions.

More posts like this

- One Piece Flow Manufacturing: The Key to Boosting Efficiency? - One piece flow is a lean manufacturing method that can be a central part of improving efficiency by increasing productivity, reducing waste and boosti...

- The benefits of lean manufacturing for the food and beverage industry - Lean manufacturing and Total Quality Management (TQM) first came about through the work of Henry Ford, followed by Toyota in Japan. They set about to ...

- Inventory Management: A Difficult Endeavor? - In an inventory-heavy business, effective inventory control is important, and perhaps even critical, to ongoing success. Whether you’re a FMCG whole...