Stock-keeping-unit (SKU) rationalisation is an inventory management method for improving the performance and profitability of your business. It involves identifying and removing low-performing or redundant SKUs for an optimised product portfolio.

This article looks at the SKU rationalisation process, how to utilise SKU rationalisation analysis for your business, and some essential best practices for implementing it.

What is SKU rationalisation?

SKU rationalisation is the process of analysing and optimising your product portfolio. It involves the identification and elimination of low-performing or unprofitable products and the prioritisation of those that generate the most value for your customers and the greatest revenue for the business.

As a business strategy, SKU rationalisation helps you to reduce business costs, improve inventory management, increase operational efficiency, and enhance your brand image.

Here are three examples of SKU rationalisation in practice:

- A clothing retailer decides to reduce the number of colours, sizes, and styles of its products based on sales data and customer feedback. This helps them simplify their inventory management, reduce storage and distribution costs, and offer a more consistent and appealing product range to their customers.

- An electronics manufacturer chooses to discontinue older or less fashionable design models, based on market trends and customer preferences. Discontinuing lines will help the manufacturer free up production capacity, and redirect research and development spending to focus on the development and marketing of newer or more innovative products.

- A food and beverage company decides to streamline its product portfolio, based on the nutritional value and environmental impact of its products. This helps them to meet the changing consumer demands for healthier and more sustainable products. It helps align the company’s products with its corporate social responsibility goals and differentiate itself from competitors.

SKU rationalisation is identifying the products that are most valuable to your customers and most profitable for your business then eliminating or reducing the ones that are not. This means that SKU rationalisation can help a business save on costs, increase sales, and enhance customer satisfaction.

What is the SKU rationalisation 80/20 rule?

The SKU rationalisation 80/20 rule is based on the Pareto Principle and helps businesses optimise their product portfolio and inventory control. It was derived from the idea that 80% of your sales or profits come from 20% of your products or customers.

The SKU rationalisation 80/20 rule also helps you to identify and eliminate any obsolete, slow-moving, or low-margin products that are taking up both space and resources. By focusing on your more profitable and popular products, you can reduce overheads, improve customer satisfaction, and increase your organisation's overall efficiency.

Benefits of SKU rationalisation

Benefits of SKU rationalisation

The benefits of SKU rationalisation are manifold. It helps to reduce your inventory costs, improve operational efficiencies, enhance customer experience, and increase your sales and profit margins.

Key benefits of SKU rationalisation include:

- Easier inventory tracking of every SKU. Using metrics such as inventory turnover rate, sell-through rate, and gross margin return on investment allows you to monitor your inventory performance more effectively.

- Improved inventory accuracy. SKU rationalisation facilitates easier tracking and management of inventory levels. You can avoid overstocking or understocking issues by discontinuing SKUs such as seasonal stock, niche products, or unpopular sizes and colours.

- Reduced storage and supplier costs. The discontinuation of SKUs that have low sales volumes, high return rates, or high storage costs, can save on warehouse space, and handling fees. You can keep your purchasing costs down by stocking only the SKUs that generate profit and demand.

- Streamlined processes for order picking, packing, and shipping. By consolidating SKUs with similar features – such as flavour, size, or shape – you can simplify your order fulfilment process. With fewer SKUs to manage you can reduce the risk of any errors and delays.

- Greater accuracy of SKU replenishment triggers. Setting data-driven thresholds for each SKU based on its sales performance and seasonality can help you optimise your inventory replenishment strategy and avoid inventory waste.

- Research and design opportunities. By removing obsolete or slow-moving SKUs and ones with outdated ingredients, packaging, or claims you can then identify and introduce new SKUs. Ones that cater to emerging customer segments, such as environmentally sustainable, organic, or cruelty-free products.

Reviewing and adjusting your company's product range through SKU rationalisation means you’re getting rid of products that no longer serve your business.

Removing stock that doesn’t contribute to profitability or customer satisfaction provides opportunities to differentiate your business with new SKUs and unique value propositions, such as novelty, convenience, or health benefits.

How the SKU rationalisation process works

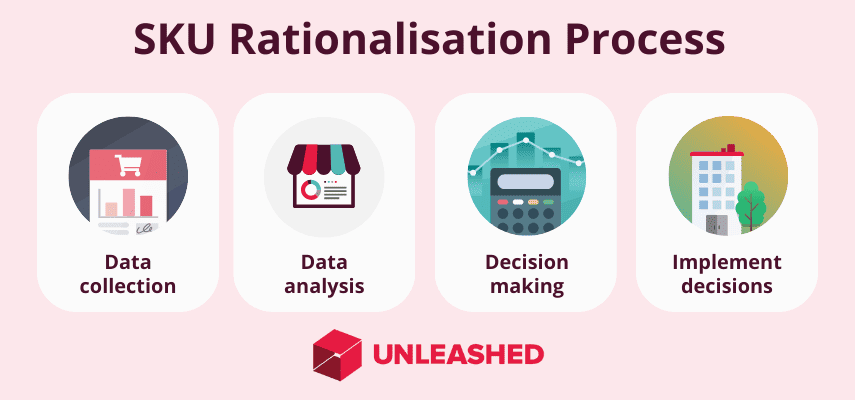

The SKU rationalisation process works through a four-step procedure consisting of:

- Data collection

- Data analysis

- Decision-making

- Implementation

Let’s explore this process in more detail.

1. Data collection

Data collection is where you gather all the relevant information on your current SKUs using factors such as sales volumes, profitability of each SKU, market trends and customer feedback.

For this step, you must segment your SKUs into categories based on the attributes of each, such as the type, brand, size, and colour of the products. Then collect and evaluate historical data around sales history, demand patterns, inventory levels, and the costs of each SKU.

Identify consumer demand by undertaking market research to better understand what it is your customers want and need, and how their purchasing preferences may change over time. You can conduct surveys and use feedback forms, product reviews, and social media activities to gather data on customer behaviour and satisfaction.

Remember to consider external factors such as current market conditions and competition that may affect your product range.

2. Data analysis

Data analysis is easy when you employ the use of various tools and techniques that help you evaluate the current performance and future potential of each SKU.

Identify and rank the SKUs you need to be rationalised based on your objectives and criteria before applying a selected method to rank your SKUs.

Methods you can use to analyse your SKU and sales data include:

- The SKU rationalisation 80/20 rule

- ABC analysis

- Product life cycle analysis

- Customer segmentation

You can evaluate the performance of each SKU using metrics like sales volume, inventory turnover, storage costs, customer acquisition costs, revenues and margins.

Inventory management software, spreadsheets, and analytic tools can be used to collect and organise your SKU data, resulting in a list of SKUs that are candidates for elimination or reduction.

This short video explains how software helps facilitate SKU rationalisation:

3. Decision-making

Decision-making is where you take all that data collected and analysis results and apply a set of rules and criteria to determine which SKUs to keep, modify, or eliminate.

Define your objectives and criteria for SKU rationalisation.

What are the key performance indicators you want to improve, and what are the benchmarks that you’ll use to evaluate each SKU?

Data-driven decisions enable you to identify gaps and opportunities in your product portfolio where you can introduce new and improved SKUs to meet consumer demand.

Once you’ve organised your product catalogue, you can use this data to inform smart decision-making. For example, you may choose to order more of your best-selling SKUs and adjust your pricing and promotion strategies for your medium-performing SKUs, while opting to liquidate and discontinue your non-performing SKUs.

4. Implementation

Implementation of your SKU rationalisation process refers to the execution of your data-based decisions: You have decided which SKUs to rationalise and now you need to communicate them to all relevant stakeholders, such as your employees, suppliers, distributors, and customers. Then you must implement and monitor the changes.

Track the impact of the changes on your KPIs using dashboards and reports to measure results and customer feedback. Periodically review and update your SKU rationalisation process and adjust as and when needed.

How to perform SKU rationalisation analysis

SKU rationalisation analysis takes an in-depth look at your current inventory to help you decide which products to add, remove, or keep. By removing underperforming SKUs you can improve your stock control, reduce your overhead costs, and increase your profit margins.

To perform an SKU rationalisation analysis, you need to track and measure the profitability of each of your inventory SKUs.

You can conduct an SKU rationalisation analysis using metrics like:

- Inventory holding costs: Measure the cost of holding, storing, insuring, and maintaining your inventory over time.

- Procurement fees: This covers the total cost to you of sourcing and purchasing your products from suppliers or manufacturers.

- Order fulfilment metrics: These determine the cost of picking, packing, and shipping products to your customers.

- Customer acquisition costs: Calculate the cost of marketing and promoting your products to attract and retain customers.

- Historical sales data: This considers the past performance of your products in terms of sales volume, revenue, and customer demand.

6 SKU rationalisation best practices

SKU rationalisation best practices aim to help businesses eliminate slow-moving, redundant, and obsolete stock. They provide a means of improving efficiency and customer satisfaction by focusing on the items that generate the most value and demand.

1. Audit your product portfolio

Undertake the four key steps of SKU rationalisation by conducting a thorough stock analysis of your current portfolio and identifying the criteria for evaluating each.

Rank SKUs based on that criterion, assigning them to distinct categories before deciding which to keep, reduce, expand, or eliminate. Implement the changes in a phased manner and clearly communicate changes to stakeholders. Don’t forget to monitor and measure your results.

2. Have a clear understanding of who your target market is

Knowing your customer helps you to align your product portfolio with the needs and preferences of your target market. By understanding what your customers want, need, and value, you can rationalise your SKUs accordingly.

Base your product assortment on the needs of your target market.

You should also consider any other variables such as seasonality, demand fluctuations, customer feedback, and competitive analysis to ensure you are offering the right products to the right people at the right time.

3. Integrate SKU rationalisation with your holistic business strategy

Align your SKU rationalisation with other critical business goals, in conjunction with your overall business strategy. Consider how your portfolio of SKUs supports your brand identity, target market, value proposition, and differentiation.

Your SKUs should also align with your supply chain capabilities, such as lead times, sourcing, quality, and delivery.

You need to be able to sell your products efficiently without running into stockouts.

4. Focus on the core competencies of your business

Offer products that meet or exceed your customers’ expectations where they see value for money in your products. By regularly scrutinising and assessing which SKUs you sell, you can identify buyer gaps in your catalogue.

If your business is operating successfully against close competition yet lacks a specific product, you should work this into your short-term goals. The more value you can offer consumers compared to the competition, the more profitable your business becomes.

5. Establish a SKU rationalisation schedule

Designate time to review your SKUs regularly – at least once annually – using data-driven criteria to evaluate their performance. When scheduling days for inventory cycle counting and ABC analysis, apportion time to count your number of SKUs.

SKU rationalisation can be done periodically based on market trends, customer feedback, inventory levels and other factors. Use inventory management tools and software for quicker, more accurate reporting.

6. Incrementally appraise and monitor SKU rationalisations

Implement a continuous process of testing and validating their impact on your sales, profits, and customer satisfaction.

You should evaluate your rationalisations incrementally by removing or reducing a few SKUs at a time and measuring their effects on key performance indicators. Seek feedback from your customers, suppliers, and employees to ensure that your rationalisations are beneficial and not detrimental to your business.