Stock keeping unit (SKU) codes are everywhere. You'll find them built into sales analysis platforms, as part of an SKU system for managing inventory, and broken down line-by-line in various inventory reports.

This guide contains everything you need to know about the meaning of SKU and the best practices for SKU management, with actionable tips and examples to set you off on the right track. Now let's get started.

What is SKU?

SKU stands for stock keeping unit and can be defined as a unique code assigned to an individual product to improve traceability and inventory management efficiency.

SKUs are the basic building block of managing inventory in warehouses, factories, and retail stores. They help product businesses track inventory more efficiently and calculate optimal stock levels. Stock keeping units can also help determine a company's inventory turnover and profitability.

If two products differ in any discernible way, they cannot have the same SKU code.

Is SKU the same as Universal Product Code (UPC)?

While some people use SKU and UPC interchangeably, they are quite different and have different functions.

SKUs are unique alphanumeric codes assigned to individual products so that businesses can track inventory with greater efficiency. Universal Product Codes, on the other hand, are 12-digit numbers assigned by a group called the GS1.

A SKU number is generated internally within a company. If the same product were to be held by two different companies, those products would have two different SKU codes. Conversely, a UPC or Universal Product Code is consistent regardless of which company buys or sells the product. UPC codes stay with the product for its entire shelf life no matter where in the world it is bought or sold.

To summarise: Both UPC codes and SKU codes are numbers used to identify products. However, a product will only ever have one UPC but it could have any number of SKUs for each of its variations. If products are completely identical (not variations of one another), they should have the same SKU.

What are SKU codes used for?

SKU codes are used to identify and track inventory.

Businesses that use SKUs have access to unique data that helps predict future demand.

Retail stores need to determine optimal reorder points based on demand. Manufacturers need to order the right ingredients to produce enough stock to keep up with demand. And online retailers rely on accurate stock levels to fulfil online orders.

By measuring the historical performance of different SKUs, you can maintain optimal stock levels in the warehouse or on the sales floor. This helps prevent stockouts, ultimately improving customer loyalty.

When each product has its own stock keeping unit, it also prevents confusion over what make, model, brand or specification of a product a customer ordered, because there's only one code for every permutation.

SKU examples

SKUs are alpha-numeric codes – this means that they use both numbers and letters.

They are designed to be legible by humans at a glance and offer important information.

Some examples of common SKUs:

-

A blue, cotton T-shirt, size medium: T-COT-MED-BL

-

A 1kg jar of chocolate peanut butter: PB-1KG-CHOC

-

An A/C condenser made by “Air Co.”, part number 3369, designed for a Toyota car: AICO-ACCON-3369-TOY

As you can see, the SKU number often reveals distinguishing features about a product. For example, the example SKU number above for a T-shirt communicates its type, material, size, and colour.

Why are SKUs important? 5 major benefits

SKU numbers are primarily used to help businesses better manage inventory, track products, and make smarter inventory purchasing decisions. However, SKU numbers and the data they produce offer additional benefits as we'll get into now.

1. Clarify subtle differences between products

Without SKU codes, product variants can cause confusion at all levels of your supply chain.

Imagine you're a manufacturer that produces and sells peanut butter. In the beginning, you have a single product in a single size, with no additional variations. But after a while you decide to produce different types and volumes of peanut butter.

Where once there was only 1KG crunchy peanut butter available, there is now smooth peanut butter and multiple sizing options. To distinguish between the different types and sizes, you would create new SKUs for each variant.

In this way, your SKU numbers help you more easily manage multiple variations of your original peanut butter product.

2. Encourage shoppers to buy more

Because SKU numbers are logical and digital, they can be helpful in automation.

SKU numbers are highly effective tools for grouping like products together.

If a customer buys one particular product from your online store, for example, they can be automatically recommended similar products based on your SKU codes.

If you were selling video games, perhaps a a complementary video game offer pops up. Or in the case of shoe retailers, it may be a pair of matching socks or shoe cleaner that's offered in tandem with the original product.

3. Faster customer service

Customers don't like to wait around for salespeople to check the back of the store for products.

SKU numbers – correctly updated and stored in an inventory system – mean that salesperson can quickly enter a code on a computer or scan a barcode to determine current inventory levels for every variation of every product.

Because the customer doesn't have to stand idle at the counter or wait patiently on the phone, they will have a better experience and be more likely to complete their purchase.

4. Easier to track inventory in the supply chain

Stock keeping units are mission-critical in any warehouse, manufacturing, or retail store environment because they make it easier to track and analyse inventory.

How? By enabling each link in the supply chain to refer to goods with a common language.

From the manufacturer to the retail store, a single SKU can be tracked as it passes through each key stage. This provides better visibility over your products so you can better plan and prepare for sales.

5. Improve cost efficiency

SKU numbers enable businesses to compare sales and purchasing data between different product variants – for example, how red shoes sell compared to blue shoes.

You can use this information to inform your product development and sales strategies, minimise inventory shrinkage, and reduce the cost of producing and storing inventory.

These benefits make it clear that implementing a SKU management system is a no-brainer for most businesses. However, there are some caveats to this which we'll explore now.

Challenges of managing SKU numbers

While a SKU number is a handy tool for tracking goods in your business, there are a few pitfalls you ought to be aware of right now. Here are some common challenges of managing SKUs.

1. Keeping your stock keeping unit numbers simple

SKUs should be as simple as possible.

Avoid making them too long or complex to read; they're meant to be digestible at a glance. This is why SKUs contain both numbers and letters as opposed to just numbers – it allows for much clearer delivery of information.

Second, avoid copying your supplier or manufacturer's codes where possible.

Copying supplier's codes will cause confusion in future. Develop your own internal language by ensuring each SKU functions as a unique identifier for that product.

2. Keep it consistent

When developing your language, bear in mind that you'll want to stick with it for some time.

To be more effective, SKU codes need to be consistent with each other so you won't want to change them in future.

The benefit of consistent styling for your SKU numbers is that it means whoever is managing your purchase orders, POS system, and accounting software can all see the same code and understand it instantly.

3. Be wary of certain characters

Characters like 0 and O look very similar in certain fonts, as do lower-case L and upper-case I. Try to avoid using them unless they are within a clear context.

Generally, it's best to avoid using them on their own.

Special characters such as '/' or ', @, #, and !' should also be avoided. This is because they may not format correctly in some software, and can reduce the clarity of your SKU number.

How do you generate a SKU?

To generate SKU numbers, you may create a SKU yourself or use a free online stock keeping unit generator.

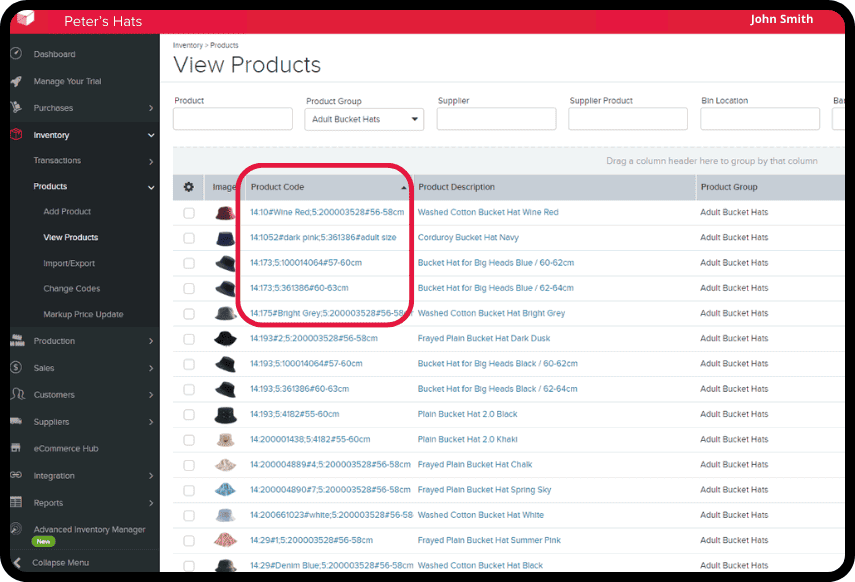

If you're using a SKU management system – for example, inventory control software – you can set up unique SKUs whenever you add a new product. SKUs in Unleashed, for example, are found in the Product Code field and can be added manually or uploaded in bulk from an external source.

How stock keeping units can be tracked in an inventory management system for easier product control.

How stock keeping units can be tracked in an inventory management system for easier product control.

What is SKU rationalisation?

SKU rationalisation is the process of determining a product's cost efficiency by using SKU codes compared with inventory and sales data to develop detailed profitability reports.

By understanding the complete life and value of individual products, organisations can make informed decisions on whether to discontinue the product, or refocus their marketing efforts.

The process is sometimes referred to as inventory optimisation or product optimisation.

SKU rationalisation can help you:

-

Discontinue unprofitable SKUs

-

Reduce inventory shrinkage by detecting SKUs with high wastage

-

Improve inventory forecast accuracy

-

Reduce inventory carrying costs

-

Optimise supplier relationships based on sales value

-

Optimise team size based on new inventory needs

Let's dive a little deeper into why SKU rationalisation is so helpful for store owners.

Determining profitability per product with SKUs

By working out your SKU ratios and comparing that to sales ratios, you can identify which SKU ranges are performing well and which aren't.

Here are some helpful definitions:

-

SKU ratios: This is the ratio (percentage) of your total SKUs that sit within a certain gross profit range. Say you have 100 SKUs across the business, and you understand the gross profit (price minus cost) of each, you can establish how many of your SKUs fall within each profit range of your business. For example, one range might contain 40% of all 100 SKUs, while another has merely 5%.

-

Gross profit range: A series of ranges that help you quickly categorise products based on their profit. For example:

-

Less than $4.99

-

$5 to $9.99

-

$10 to $19.99

-

$20 and higher

-

-

Sales ratio: This is worked out the same as a SKU ratio, but uses sales units instead of SKU. So, you are working out how your sales units are divided by profit range.

What to do with this information

If you take the time to work out both ratios, you can chart them against each other to help you understand which SKUs are making the best returns for the time and how much money is required to service them.

For example, when the sales ratio in a profit range is higher than the SKU ratio it means those SKUs are performing well. But when the SKU ratio is higher than the sales ratio, it means those products are underperforming.

It's important to note that this is a very manual approach to SKU rationalisation.

A more effective way for a product business to analyse their SKU performance is to use a SKU system that features a Business Intelligence function that's built into – or integrated with – your inventory management system.

Useful SKU metrics

A major benefit of using your own SKUs to track and manage products is that it creates plenty of useful data for you to track, analyse, and act on. Here are some of the most practical SKU metrics for tracking success.

1. Days Inventory Outstanding

Days Inventory Outstanding (DIO) measures the number of days you hold a particular product before turning it into a sale (or manufacturing it into a product).

Understanding this metric helps you identify products that are soaking up costs by sitting in your warehouse for too long.

The formula for calculating Days Inventory Outstanding is:

Average Inventory / COGS × Number of Days = DIO

If the DIO of a particular SKU or range of SKUs is high, it means they're not converting to sales quickly, which could mean the product has been overstocked.

Low DIO is good for cash flow, but a very low DIO could mean your organisation isn't prepared for a sudden spike in demand – something to address before running any new marketing campaigns for that product line.

2. Inventory turnover

Inventory turnover measures the number of times in a given period, usually a year, that your organisation sells its entire value of inventory. It can be used to determine inventory efficiency.

The formula for calculating inventory turnover is:

COGS / Average Inventory Value = Inventory Turnover

A low figure means you are either overstocking or goods simply aren't selling.

By drilling into turnover by SKU, you can work out – to the individual product level – which products are the problem areas of your business.

3. Order fill rate

This formula will help you with demand planning for certain products. It shows what percentage of orders are being filled with all the agreed line items versus the number of actual customer orders.

It's worked out by dividing the former by the latter – orders filled completely (that is, the first shipment contains all lines and quantities) divided by the total number of customer orders shipped, turned into a percentage.

The formula for calculating order fill rate is:

Orders Filled Completely / Number of Customer Orders Shipped × 100 = Order Fill Rate

A low fill rate means customers aren't getting what they paid for in a timely fashion, which could lead to poor satisfaction and lost future revenue.

Fill rates worked out with the help of SKUs can help you identify items that are selling more than their forecasted amount, so you can better set inventory levels in future.