A backorder presents an opportunity for businesses to continue to make sales on products that are temporarily out of stock. Goods available to be purchased on backorder can mean the difference between a lost sale and a satisfied customer.

If you’re new to order fulfilment and inventory management, you'll need a firm understanding of the backorder process. That’s why we’ve used this article to break down what backorders are, how they can be managed efficiently, and the pros and cons of having products on backorder.

What does backorder mean?

A backorder is a customer order that could not be fulfilled immediately but will be shipped out once the ordered items become available. Putting an item on backorder reserves future stock for a specific customer. Products available on backorder are out of stock in the supplier's warehouse but may still be purchased by consumers in advance of future availability.

In short, a backorder occurs when a customer places an order for a product that is currently out of stock or unavailable.

Instead of cancelling the order, the vendor reserves the item for the customer with the promise of the order being fulfilled as soon as new stock arrives or is produced.

While a backorder is not the preferable way to sell products, it is a way for businesses to maintain customer satisfaction by preventing the loss of potential sales and keeping customers engaged, despite an item being temporarily out of stock.

Backordering helps companies balance supply and demand. This reduces the risk of losing customers to competitors and streamlines the process of restocking and delivering backordered products.

Backorder vs out of stock

The difference between a product that’s available on backorder and one that’s out of stock is how the vendor manages customers’ orders when products are unavailable. Some companies will say a product is ‘out of stock’ if they don’t have any units of that item for immediate purchase. Customers cannot place orders for the item until new stock arrives.

Here’s a short summary:

- A product that’s available on backorder may still be purchased by customers.

- A product that’s out of stock (and not available on backorder) cannot be purchased by customers until it’s back in stock.

Backordering comes into play when a customer wants to buy a product that is currently unavailable and the wholesaler or retailer allows them to place an order for the item. This way, the customer can secure a product on the proviso of the order being processed once it’s physically restocked.

A backordering strategy maintains a customer’s interest and loyalty while the company manages its inventory. The inability to purchase out-of-stock goods will usually send a customer elsewhere.

How long do backorders take?

Backorder time is based on a variety of considerations. How long a backorder takes to be fulfilled can be influenced by factors such as your supply chain, manufacturing process, shipping times, and the popularity of the product.

With significant supply chain disruptions during the global pandemic, many businesses believe operating with at least some backorder of products has become the new norm. The American National Association of Manufacturers (ANAM) found that 88% of manufacturers cited supply chains as their primary business challenge.

But while backordering may be commonplace in a post-pandemic world, there are still certain customer expectations that must be met. Namely, they want their items sooner rather than later, and they want delivery promises kept.

Why it's important to track backorder efficiency

To keep those promises, it’s important to understand the average time for backorder fulfilment in your business. You can work out how long backorders take by identifying your typical lead times, production times, and fulfilment times.

In some cases, backordered items might be restocked relatively quickly, especially if you have a well-established supply chain and the product is in high demand. In other instances, backorders could take longer if there are delays in production, sourcing materials, or unforeseen logistical challenges.

It’s best practice to provide estimated timelines for backordered items, and also make customers aware that these are not set in stone and can change due to various circumstances. Ensure you stay in touch with customers to keep them updated on the status of their backorder.

Ultimately, the time a backorder takes can't be generalised since it's determined by internal and external factors that change from one situation to another.

How backorders work: The backordering process explained

The process of backordering involves several steps that a vendor must take to manage customer orders for products that are currently not in stock.

Here's a simplified outline of the backordering process:

- Customer order: A customer places an order for a product that is out of stock or unavailable.

- Backorder placement: Instead of rejecting or refunding the order, the business lets the customer place a backorder. This means the company records the customer's request for the item, even though the order cannot be physically fulfilled right now.

- Confirmation of backorder: The company acknowledges the backorder and provides the customer with an estimated timeline for when the product is expected to be back in stock and when their order will be fulfilled.

- Inventory management: The business keeps track of all backordered items while monitoring their inventory levels. They might prioritise restocking the most popular or high-demand items to fulfil backorders more efficiently.

- Restocking and production: The company works on restocking the product through manufacturing, sourcing, or acquiring the necessary inventory. This step can take varying amounts of time based on factors like production capacity, supplier availability, and any potential production challenges.

- Order fulfilment: As soon as the backordered product is available and quality-checked, the company ships the product to the customer.

- Customer notification: The customer is notified that their backorder has been fulfilled and that the item has been sent. This notification will usually include tracking information so the customer can monitor the progress of their shipment.

It's important to note that the specifics of the backordering process can alter between companies and industries. The aim is to bridge the gap between customer demand and product availability while providing a positive and successful customer experience.

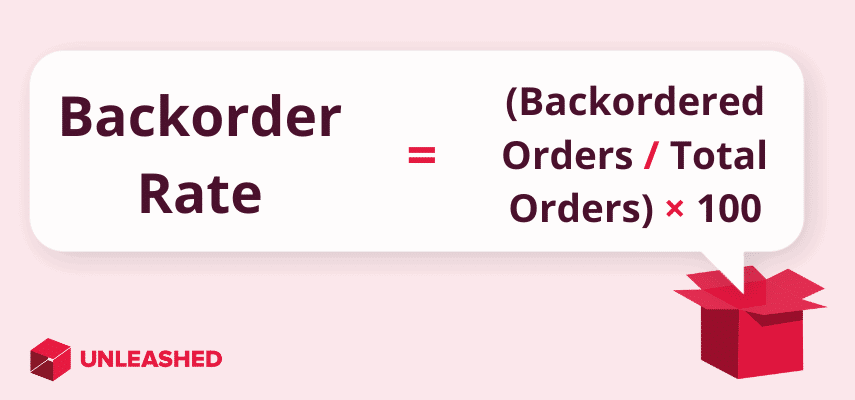

Calculating backorder rate

Backorder rate is a vital inventory metric because it shows how well your business performs when stocking products to keep up with customer demand. This is something you should measure on a regular basis to understand which portion of orders are backordered, as it will provide crucial insights to assist with decision-making.

To calculate backorder rate, use the backorder formula:

(Number of Delayed Orders Due to Backorders / Total Number of Orders Placed) × 100 = Backorder Rate

Backordering: Pros and cons

Backorders can cost your company 10% or more in lost sales. But while backordering can be a difficult and expensive process to manage, there are many benefits to allowing backordering in your company.

Let’s dive into the pros and cons of backordering.

Advantages of backorders

- Maintaining customer loyalty: Backorders allow customers to secure the items they want, even when they're temporarily out of stock. They also provide them with the flexibility to place orders even when a product isn't immediately available, giving them more control over their purchasing decisions.

- Minimising lost sales: Rather than losing potential sales when a product is out of stock, backordering enables businesses to capture orders and revenue from customers who are willing to wait.

- Reducing inventory costs: Backordering helps companies avoid overstocking, which can tie up cash flow and storage space. Instead, they can manage inventory more efficiently based on actual customer demand. This information helps in making more accurate production and restocking decisions.

- Maximising production efficiency: Backorders can guide production management and planning. Manufacturers can adjust their production schedules based on the number of backorders, ensuring they produce the right quantities without excess waste.

- Avoiding rush orders: Instead of rushing production to meet immediate demand, companies can fulfil backorders as new stock becomes available. This reduces the need for expensive expedited production processes.

- Avoiding competition: Customers who place backorders are less likely to shop with competitors in search of the desired item because they've already committed to purchasing from the company.

Backorders enable businesses to enhance the customer experience, optimise their inventory management, and make informed decisions about production and restocking. It's a strategy that can positively impact both short-term revenue and long-term customer relationships.

Disadvantages of backorders

Before you decide that backorders are your best solution to stock-outs and lost revenue, let’s cover some of the disadvantages of a backorder strategy.

- Customer frustration: Extended wait times for backordered items can lead to customer dissatisfaction. They might become impatient and cancel their orders, resulting in lost sales (and negative reviews).

- Potential order cancellations: If customers lose interest or find alternative sources for the product during the backorder period, it can lead to order cancellations. This can disrupt revenue projections and leave you with surplus stock on hand.

- Cash flow impact: While backorders can secure future sales, they might not immediately generate revenue. This can disrupt or restrict your cash flow.

- Inventory accuracy challenges: Managing backorders requires accurate inventory tracking. Mismanagement can result in over-promising and under-delivering, increasing customer dissatisfaction.

- Complex warehousing logistics: Fulfilling backorders involves coordinating production, shipping, and delivery. Delays or disruptions in any of these stages can further prolong the backorder fulfilment process. You may also need to allocate additional resources to handle backorders.

- Demand uncertainty: Predicting the exact number of backorders can be challenging, leading to potential overproduction or underproduction if demand varies significantly.

While backorders can be a useful strategy, businesses need to balance their advantages with these potential drawbacks. Careful planning, efficient inventory management, and effective communication are key to minimising the disadvantages of backorders and maximising their benefits.

Backorders in supply chain management: 10 essential backorder best practices

If you think backordering will work for your business, then the next step is establishing a process that incorporates the best-practice elements of backordering.

10 backorder best practices you ought to follow:

- Accurate inventory tracking: Maintain precise records of your inventory levels. Regularly update your system to reflect incoming stock and prioritise fulfilling backorders promptly.

- Transparent communication: Regularly keep customers informed about the status of their backorders. This will help to keep them assured while they wait and minimise incoming queries asking for updates.

- Flexible order management: Allow customers to modify or cancel their backorders if their circumstances change. Flexibility can lead to higher customer satisfaction when dealing with your business and encourage them to return in the future.

- Automated notifications: Use automated systems to send notifications to customers when their backorders are fulfilled and shipped. This streamlines communication and enhances customer experience.

- Set clear backorder policies: Have well-defined backorder policies that outline how the process works, including cancellation options, refund policies, and customer communication standards.

- Alternative product suggestions: If possible, suggest alternative products to customers while their desired item is on backorder. This helps prevent them from seeking similar items elsewhere.

- Realistic estimates: Provide realistic estimated delivery dates and immediately update customers if there are any changes. It's better to exceed expectations than to promise quick fulfilment and disappoint customers.

- Efficient supplier relationships: Maintain strong relationships with suppliers to ensure timely access to the materials needed for production. Clear, proactive communication can help minimise potential delays.

- Quality control: Ensure that backordered products meet your quality standards before shipping them to customers. This helps avoid returns or dissatisfaction.

- Continuous improvement: Regularly assess your backordering process to identify areas for improvement. Gather feedback from both customers and internal teams to refine your approach.

Remember, the best practices you choose to implement will depend on your specific industry, business size, and customer base. Tailoring these practices to suit your organisation's needs will help you effectively manage backorders while maintaining customer satisfaction.

Backorder notification example

If you allow backordering in your business, it’s recommended that you have a standard communication in place to inform customers that their product is on backorder.

Here’s an example of a backorder notification:

Subject: Important Update Regarding Your Order

Dear [Customer's Name],

We hope this message finds you well. This is an update regarding your recent order #[Order Number] for the [Product Name] that you placed on [Order Date].

Due to the unexpectedly high demand for this product, we regret to inform you that it is currently on backorder. Our team is working diligently to restock the item and fulfil your order as soon as possible.

Estimated Fulfilment Date: [Estimated Fulfilment Date]

Estimated Shipping Date: [Estimated Shipping Date]

Please note that these dates are subject to change based on supplier availability and other unforeseen circumstances. However, please rest assured that we are doing everything we can to expedite the process and get your order to you as soon as possible.

We understand the importance of your order and sincerely apologise for any inconvenience this delay may cause. We greatly appreciate your patience and support. If you would like to modify or cancel your order, or if you have any questions, please feel free to contact our customer service team at [Customer Service Email or Phone Number].

Thank you for choosing to buy from us. We value your business and are committed to providing you with the best products and services.

Best regards,

[Your Name]

[Your Title]

[Your Company Name]

[Customer Service Email]

[Customer Service Phone Number]

This is just a template, and you can customise it according to your company's brand tone and specific details. The key is to provide clear information about the backorder status, estimated fulfilment and shipping dates, and contact information for customer inquiries.

How to efficiently manage backorder inventory

Efficiently managing backorder inventory involves a strategic approach that balances customer satisfaction, inventory optimisation, and operational effectiveness. Here's how backorder inventory can be managed effectively:

- Maintain accurate inventory: Implement a robust inventory management system that tracks incoming stock, current levels, and committed backorders in real time. This helps you make informed decisions and prevents overpromising.

- Demand forecasting: Use backorder and historical data, as well as market trends, to forecast future demand for backordered items and guide production decisions. This helps you plan production and restocking more accurately.

- Safety stock: Maintain a buffer of safety stock for popular items prone to backorders. This can help you fulfil unexpected surges in demand and minimise customer wait times.

- Supplier relationships: Cultivate strong relationships with suppliers. Timely communication and collaboration can help minimise issues and ensure a steady flow of inventory.

- Priority planning: Plan which backorders to fulfil first, based on factors like order date, customer loyalty, and product demand. This helps to manage customer expectations and allocate resources effectively. Use efficient picking, packing, and shipping processes to fulfil backorders quickly once the items are available.

- Streamlined production: Optimise your production processes to align with backorder demands. Adjust manufacturing schedules, based on the number and types of backorders, to fulfil backorders efficiently while minimising waste.

- Continuous improvement and monitoring: Regularly review your backorder performance and management processes based on metrics such as fulfilment time, changes in the market and customer feedback. Adapt to evolving customer needs and industry dynamics and use data analytics to analyse backorder trends, customer behaviour, and fulfilment cycles. These insights can guide strategic decisions and process improvements.

Effectively managing backorders requires a well-coordinated effort across various departments, from procurement and production to customer service and logistics. By implementing these strategies, you can maintain customer satisfaction, optimise inventory utilisation, and enhance overall operational efficiency.