Effective inventory management comes down to good systems, good processes, and constant improvement. The last of these can be achieved by tracking the right inventory metrics, analysing the results, and making data-driven optimisations.

So, what are the ‘right’ inventory metrics, and how do you calculate them? We look at 17 of the most important ones and the best practices for tracking them in this article.

What are inventory metrics?

An inventory metric is a measure used to understand the efficiency, effectiveness, and performance of inventory management. Metrics allow product businesses to make data-driven decisions that improve stock control processes and profitability.

Tracking the right inventory metrics will help your business reduce costs, increase sales, and keep customers happy.

What are KPIs for inventory?

Key Performance Indicators for inventory, commonly known as KPIs, are measurement tools that allow you to track the performance of various aspects of your business. They’re useful for giving insights into the success (or otherwise) of how you’ve constructed workflow and systems, and whether changes need to be made to create efficiencies.

KPIs related specifically to inventory allow you to understand how you’re managing the flow of goods, materials, and products to your warehouses and out to the customer.

Inventory metrics for sales

Inventory metrics related to sales allow you to analyse if the process to support the sales process is as efficient as it can be.

1. Inventory turnover rate

Inventory turnover rate shows how rapidly inventory is being converted to sales through the warehouse.

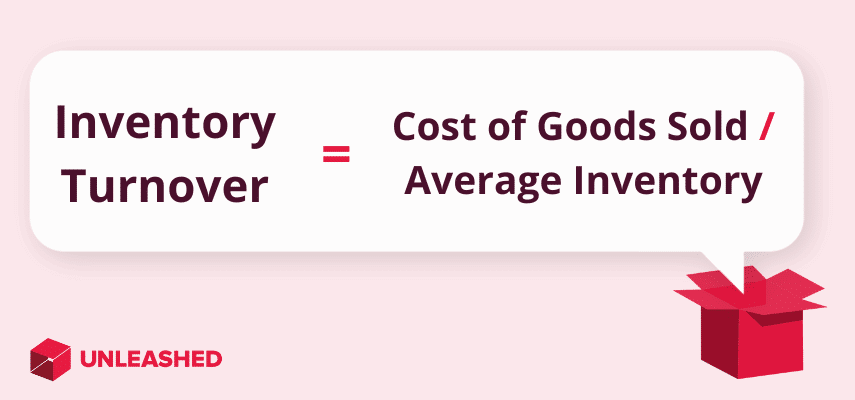

The formula for inventory turnover is:

Cost of Goods Sold / Average Inventory = Inventory Turnover

The business owner or warehouse manager should set KPIs for the inventory turnover rate relative to the business’s normal turnover and ambitions for future growth.

High turnover rates indicate your business is enjoying strong sales, and this would be reflected in the KPIs. Conversely, the KPIs will lag if the turnover is slow.

2. Cost of goods sold (COGS)

COGS shows the costs incurred by your business to produce the goods sold. This inventory metric supports your business’s ability to understand costs and figure gross profit margin.

The formula for COGS is:

Beginning Inventory + Purchases During the Period - Ending Inventory = COGS

Cost of goods sold is useful for feeding into inventory management and pricing strategies.

3. Stock-to-sales ratio

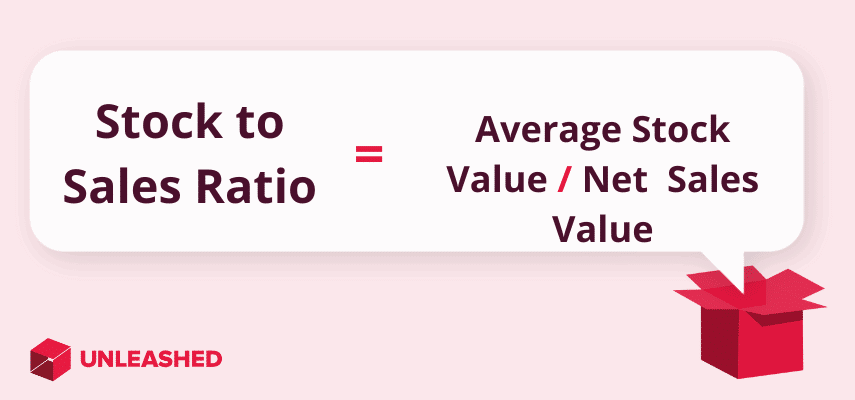

The stock-to-sales rate is a metric used to measure how efficiently you’re managing inventory. It details how many times you turn over your inventory in a certain period compared to a previous period.

This helpful inventory metric allows you to understand if goods are shifting differently than they have previously and means you can adjust your product strategy as required.

The formula for stock-to-sales ratio is:

Average Stock Value / Net Sales Value = Stock-to-sales Ratio

The ideal way to measure this is in real-time, so you have an instant understanding of how inventory is moving and can respond in a way that improves the supply chain and sales process.

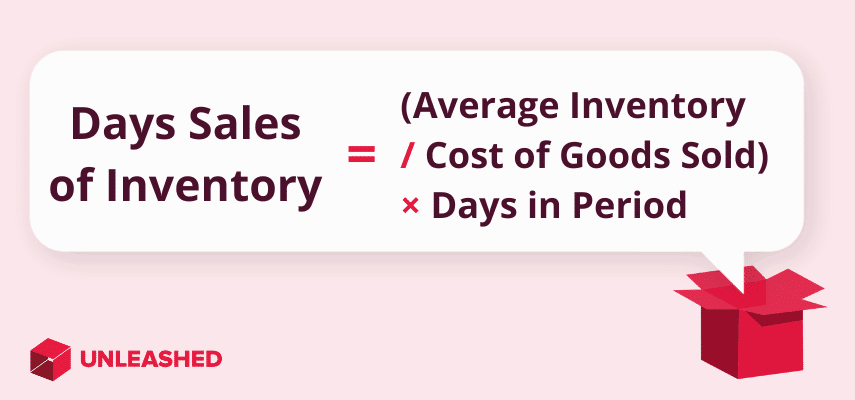

4. Days sales of inventory (DSI) / Days of inventory on hand (DOH)

These two financial inventory metrics which can be used interchangeably, allow you to measure the efficiency of the inventory and figure out how long stock is held before being sold.

(Average Inventory Value / COGS) × Number of Days = DSI

The formula for DOH is:

Average Inventory Value / (COGS / Number of Days) = DOH

Together, these key inventory metrics give you insights into the efficiencies of your inventory management systems and sales process.

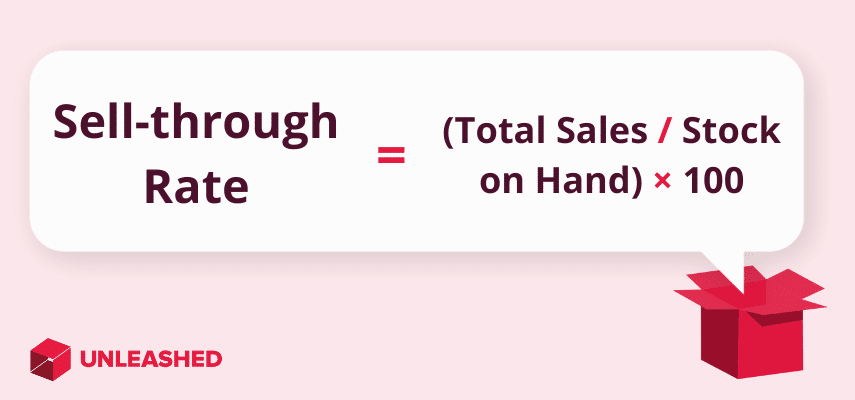

5. Sell-through rate

Sell-through rate is the percentage of your inventory which you have sold to customers. It is usually calculated monthly and allows you to change your stocking and selling strategy in response.

The formula for sell-through rate is:

(Total Sales / Stock on Hand) × 100 = Sell-through Rate

This inventory metric gives you insights into sales fluctuations, trends, and changing demands.

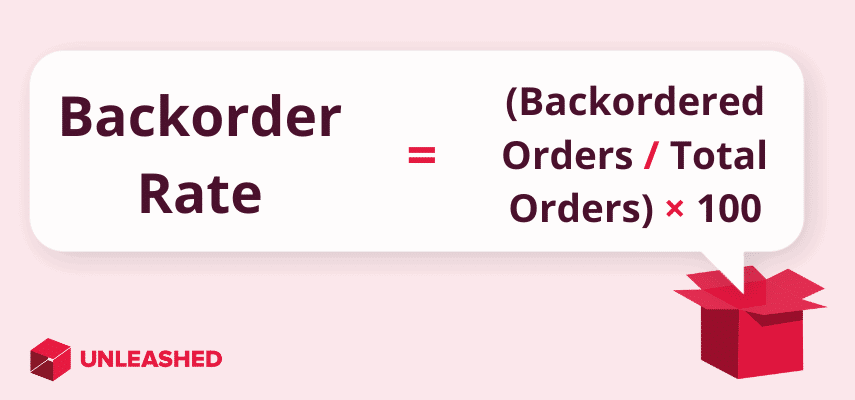

6. Backorder rate

Backorder rate refers to the number – presented as a percentage – of customer orders that are unable to be fulfilled due to stockouts, supply chain issues, or inventory glitches. This metric gives insights into the delays or problems with customer orders.

The formula for backorder rate is:

(Number of Backordered Orders / Total Number of Orders) × 100 = Backorder Rate

Backorder rate is an important inventory metric because it reveals how efficiently the entire supply chain operates, and how well customer demand is serviced.

7. Inventory-to-sales ratio

Inventory-to-sales ratio is a KPI which tracks the amount of stock you have on hand compared to orders being made. You should set the KPI with a realistic target so that staff are focused on maximising sales relative to the stock available.

The formula for inventory-to-sales ratio is:

End-of-month Inventory Balance / Sales for That Month = Inventory-to-sales Ratio

If KPIs are not being reached, consider reviewing your pricing structures, analysing your inventory management systems, and trying new strategies such as targeting different audiences.

Inventory metrics for stock control

The following inventory metrics help you measure the performance and efficiency of your stock control processes. By improving them, you will decrease workplace downtime and fulfilment costs while increasing customer satisfaction.

8. Receiving efficiency

Receiving efficiency refers to the effectiveness and productivity of the process involved in receiving goods or materials into your storage facility. It’s an important KPI used in supply chain management and warehouse management.

There are several formulae you can use to assess the efficiency of this aspect of the supply chain.

The formula for receiving efficiency is:

Volume of Received Goods / Number of Labour Hours = Receiving Efficiency

Order cycle time looks at how long the entire order process takes, including receiving.

The formula for order cycle time is:

(Delivery Date – Order Date) / Total Orders Shipped = Order Cycle Time

Another useful formula is dock door utilisation efficiency, which helps you understand the efficiency of your warehouse usage.

The formula for dock door utilisation is:

Number of Doors Used / Total Number of Dock Doors = Dock Door Utilisation Efficiency

9. Inventory shrinkage

Inventory shrinkage considers the loss of inventory due to factors such as damage, spoilage, theft, and errors.

The formula for inventory shrinkage is:

(Value of Inventory Losses / Value of Total Inventory) × 100 = Inventory Shrinkage

This formula measures the percentage of inventory losses relative to the total value of the inventory.

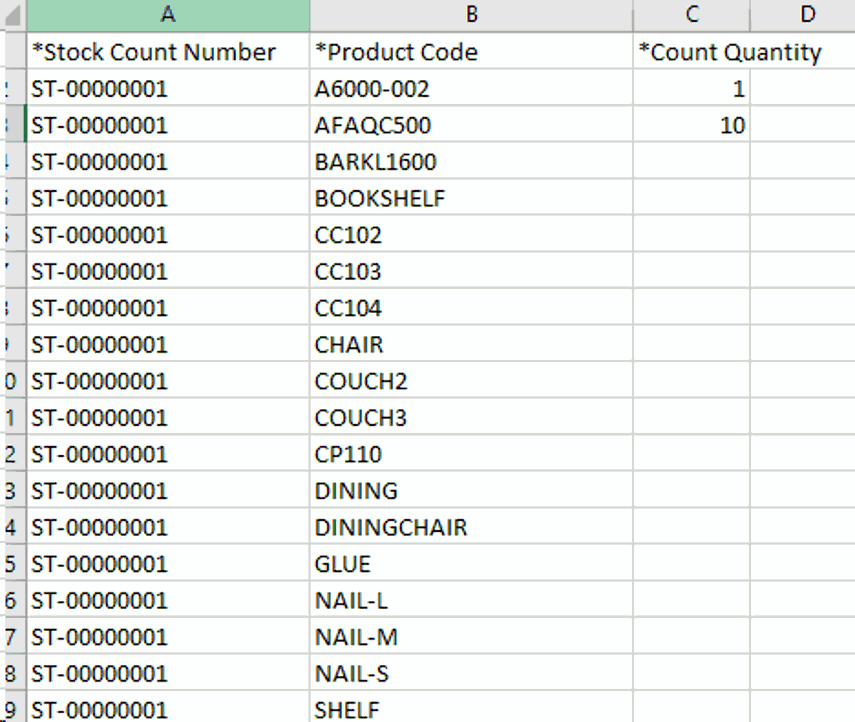

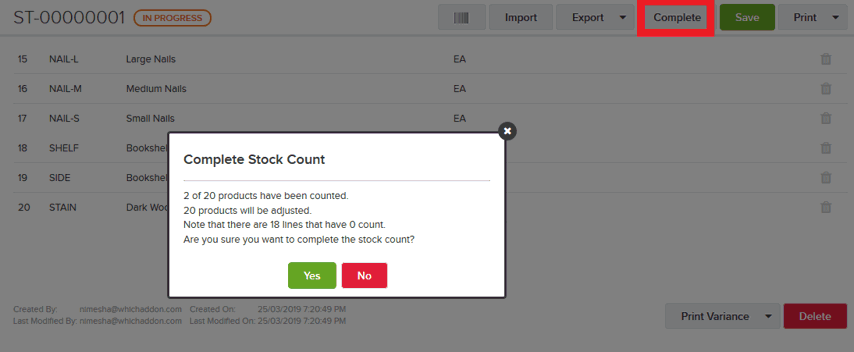

10. Inventory accuracy

Inventory accuracy ensures you track your database of products accurately. This means the information used by the business properly reflects the inventory held and can be relied on to make other business decisions.

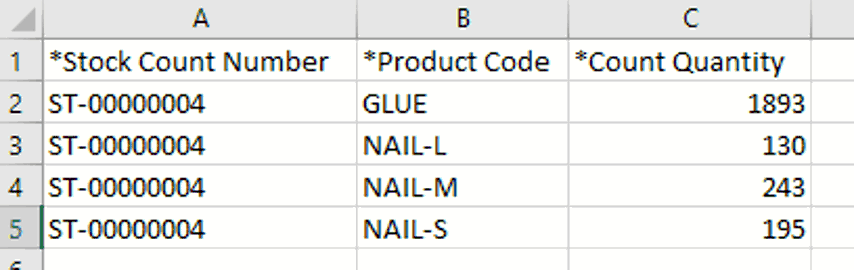

Generally, inventory accuracy is calculated through a stocktake and then comparing the results in your database.

The formula for inventory accuracy is:

Database Inventory Count / Physical Inventory Count = Inventory Accuracy

This inventory KPI needs to be tracked and measured regularly. How often is up to the inventory manager, but monthly, quarterly, and annual stocktakes are common.

Inventory metrics for order fulfilment and warehousing

Order fulfilment and warehousing metrics are important as they reflect how efficiently stock is being moved and managed on its way to the customer.

11. Order fill rate

Order fill rate measures the number of customer orders – as a percentage – that are filled on time and as expected.

The formula for order fill rate is:

(Number of Orders Filled / Total Number of Orders) × 100 = Order Fill Rate

A higher order fill rate shows a higher number of customers’ orders which were completed, which indicates more satisfied consumers.

12. Order cycle time

Order cycle time measures the time taken from order receipt to order shipment. It includes order processing time, picking time, packing time, and shipping time.

The formula for order cycle time is:

Order Shipment Time – Order Receipt Time = Order Cycle Time

A shorter order cycle time indicates faster order processing and shipment, which can result in quicker order fulfilment.

13. Order accuracy rate

Order accuracy rate measures the accuracy of orders shipped in terms of quantity, quality, and specifications.

The order accuracy formula is:

(Number of Accurate Orders / Total Number of Orders Shipped) × 100 = Order Accuracy Rate

A higher order accuracy rate indicates better product picking, packing, and shipping accuracy, which reduces the need for returns, replacements, and customer complaints.

14. Average inventory value

The average inventory value effectively measures the ‘investment’ a business has in its inventory during that period. It’s used to understand the value tied up in inventory at any one point, which can then contribute to financial analysis and business decisions.

The average inventory value formula is:

(Beginning Inventory Value + Ending Inventory Value) / 2 = Average Inventory Value

Staying across the value of your inventory is critical to understanding your business’s overall financial position. It’s a metric that should be constantly monitored and tweaked, to ensure there is the right level of investment into inventory.

Too much value locked in inventory ties up cash flow for other purposes, while too little creates the risk of stockouts or other issues.

Inventory metrics for forecasting

Forecasting is vital to smooth workflow and supply chain management. The ability to forecast has become increasingly sophisticated, with tools such as AI being able to estimate future sales potential.

15. Sales velocity

Sales velocity reflects how fast sales move through the business’s systems. It identifies a product’s full sales cycle, including how long it takes to convert a sale, its value, and the number of potential sales.

The formula for sales velocity is:

(Number of Leads × Average Deal Value × Conversion Rate) / Sales Cycle Length = Sales Velocity

The sales velocity formula helps understand how rapidly you need to reorder new products or materials. It can also inform whether the supply chain is working at the right speed to meet demand.

Sales velocity helps surface weaknesses in the sales process if, for example, there is a long delay in conversions or a high number of lost leads.

- Learn more: What is Demand Planning? [2024 Guide]

16. Optimal reorder point

The reorder point formula calculates the right inventory level a company should reach before it orders some more. This inventory metric is designed to ensure a reorder is generated before the company runs out of stock and risks a stockout.

It takes into account a number of variables, including lead time for orders and sales demand.

The optimal reorder point formula is:

(Average Daily Usage × Average Lead Time in Days) + Safety Stock = Optimal Reorder Point

Ensuring there is a reorder point for each product means your business avoids the risk of over or understocking inventory.

17. Economic order quantity

Economic order quantity is the most efficient quantity of product to order at any one time.

The economic order quantity formula is:

√[(2 × Annual Demand in Units × Order Cost per Purchase Order) / Annual Holding Cost per Unit] = EOQ

The metric considers the trade-off between the costs associated with shipping, ordering and handling goods, against the cost of holding them ready for sale. The idea is to optimise the order quantity while minimizing inventory costs.

- Looking for more metrics? Read our complete guide to manufacturing KPIs

How should you track inventory metrics?

The number of inventory metrics can be overwhelming. That’s why it’s important to choose the right metrics for your business analysis, but also to make sure they are tracked realistically and helpfully.

Below are four steps for effectively tracking inventory metrics.

1. Determine the best metrics for your business

Understand where improvements are needed and find metrics that will support that need. This could be in order fill rates, accuracy rates, warehouse utilization, or customer service.

2. Find the best way to collect relevant data

Look for the fastest and most accurate way to collect the necessary business data needed to make informed inventory decisions. This may mean investing in inventory management software, barcode scanners, warehousing equipment, or even new staff members.

3. Understand how to interpret the data

While it’s great to collect the data, you need to understand what it means and how to use it. Learn how to analyse the right data to identify trends, patterns, and areas for improvement or optimization in inventory management processes.

Inventory reporting software (like Unleashed - see demo) and business intelligence dashboards can make this much easier and more accessible.

4. Set benchmarks and usage targets for the data

Benchmarks and KPIs ensure you hold yourself and your team accountable for using the data in ways that support the business and its growth potential. There are several tools available to help track your metrics, including a few handy Unleashed add-ons.

Best practices for tracking inventory metrics and KPIs

It’s important to ensure whichever KPIs you’re monitoring have a beneficial impact on your business. Below is a simple three-step guide to putting metrics in place.

- Understand which aspects of the business may need the greatest attention. Once you have identified the most compelling needs or weaknesses in the business, you can create some KPIs and metrics that will be most beneficial in improving outcomes.

- Run through the ‘SMART’ model of analysis. SMART stands for specific, measurable, achievable, relevant, and time-bound. Running KPIs through this model ensures everyone involved has a clear idea of what is expected of them, when, and why.

- Create achievable and effective KPIs. Asking staff to meet unrealistic KPIs will ultimately damage the business, as people will become disillusioned and might even quit. Create manageable, achievable goals and rewards to improve productivity and build a sense of goodwill within your teams.

Following these three best-practice steps for tracking inventory metrics will create significant benefits for your business and your ability to manage, measure, and grow your business.