What is Manufacturing?

The manufacturing sector remains open to innovation. New manufacturers can now develop products and find their own niche with relative ease, despite competition from more established global companies.

In this guide, we’ll take a practical look at the manufacturing industry, the various production processes and techniques used in manufacturing, and how manufacturers can take advantage of modern solutions to achieve major efficiency gains.

Let’s start with some of the basics.

In this guide

What is manufacturing?

Manufacturing is the process of converting raw materials and components into finished goods. The manufacturing process can involve simple assembly by human labour or by robot, as well as mechanical, chemical, or biological processing to create a product.

Products created by manufacturers can in turn be used as components by other manufacturers in the supply chain or sold directly to end consumers.

Manufacturing can be as simple as creating bookshelves using wood, screws, glue, and varnish. It can involve more nuanced biological processes such as brewing and bottling beer using yeast, grain, water, and specialised vats and equipment.

In complex organisations, manufacturing can be as sophisticated as assembling a modern mobile phone using components sourced from hundreds of high-tech suppliers, each with its own complex global supply chain.

But how did we get here?

Raw materials to robots: A brief history of manufacturing

Manufacturing has played an important role in society for thousands of years.

In the past, manufacturers were much like builders and blacksmiths: skilled artisans whose craft-secrets were passed down by word of mouth, from one apprentice to the next.

Then came the industrial revolution of the late 18th century. Britain introduced the factory system that saw technology and advanced machinery accelerate the speed with which goods could be produced.

The production line approach divided labour so that different groups became responsible for each stage in the manufacturing process. Efficiency skyrocketed just as the cost of producing goods at a large scale plummeted.

Fast forward to modern manufacturing, where:

- Factories have been electrified and digitised to further improve manufacturing productivity and reduce the risk of human error.

- Lean manufacturing strategies enable companies to produce goods with minimised waste and a reduced risk of overproduction.

- Cloud manufacturing software exists to streamline the flow of information as goods move through each stage of the supply chain and production process.

To summarise, the manufacturing sector has received a generous injection of efficiency-enhancing solutions over the decades that continue to improve how effectively manufacturers are able to operate in modern times.

And though the industrial revolution may be behind us, innovation continues to be a key driving force in the evolution of global manufacturing.

Need accurate manufacturing inventory?

The current state of the manufacturing industry

The modern manufacturing sector remains a key contributor to the global economic environment.

In the UK, the total value of manufacturers’ product sales increased by £28.4 billion (7%) year over year from 2021 to 2022. This is hardly surprising, given manufacturing currently accounts for 45% of total UK exports – equivalent to £275 billion in sales.

The five-year compound annual growth rate (CAGR) for manufacturing labour productivity is currently -0.6% in the United States, and the five-year CAGR for multifactor productivity is -0.4%.

What does this tell us? It indicates that efforts to continually boost efficiency on the factory floor are working thanks to modern technologies and initiatives. Raw materials are converting to finished products faster and more efficiently than ever before.

10 key manufacturing sub-sectors

There is no one definitive list of manufacturing companies or industry types – different categories are used depending on the needs of a given index, government, or group.

However, commonly recognised categories of manufacturing companies include:

- Food manufacturing

- Beer manufacturing

- Pharmaceutical manufacturing

- Computer and electronics manufacturing

- Chemical manufacturing

- Furniture manufacturing

- Vehicle manufacturing

- Coffee manufacturing

- Metal manufacturing

- Spirits manufacturing

Of these, food manufacturing remains the largest sub-sector – representing over 20% of total manufacturers’ sales in 2022.

Manufacturing examples

The word manufacturing might bring to mind visions of grand factories, stacked floor-to-ceiling with fancy robotics and high-tech machinery.

While this is an accurate description of some manufacturing organisations, it doesn’t paint a broad enough picture. Technically speaking, any business that converts raw materials inventory into finished goods can be considered a manufacturing company.

Here are two examples of manufacturing that demonstrate how greatly companies within the industry may vary from one another.

Food and beverage manufacturing

Food and beverage manufacturing firms come in all shapes and sizes. For example, a globally recognisable, mass-producing doughnut factory and a small, boutique bakery that sells homemade goods both fit the definition of manufacturers.

Though it may not be equipped with all the fancy bells and whistles of large factories, the boutique bakery still converts raw materials (ingredients) into products (baked goods) – thus qualifying as a manufacturing business.

Automobile manufacturing

Unlike our boutique bakery, the automobile industry is dominated by huge factories with hundreds – or even thousands – of hired labour who each play a small but important role in producing finished goods.

Vehicle manufacturers, Toyota, for example, have a workforce of more than 21,000 people in Europe alone. They produce cars in eight manufacturing sites across six different countries and have manufactured over 13 million cars since inception.

Types of manufacturing processes

Lifting the performance of a manufacturing business requires a different approach for the different types of manufacturers. For this reasons, there are myriad manufacturing processes you might choose to implement.

The simplest distinction that can be made between different types of manufacturer comes down to what triggers their production management process.

Regardless of the huge variety of activities that can be classed as manufacturing – plus the many different industry types and production methods – any manufacturer can be classed as either:

- Make to Order (MTO)

- Make to Stock (MTS)

- Make to Assemble (MTA)

Here’s how each of these types of manufacturing processes works.

Make-to-stock (MTS) manufacturing process

Make-to-stock (MTS) manufacturing is where the manufacturer creates products in response to demand forecasting – anticipating future sales and storing finished goods so that orders can be fulfilled in the shortest possible time.

MTS manufacturing is sometimes called push production, with the forecasted demand responsible for pushing products through the production process and out into the marketplace.

MTS manufacturers are often able to create very efficient manufacturing processes. The method is suited to high-volume products with little or no variation between batches.

Today a vast array of products are created via MTS production, with so-called High Street Fashion a good example of the approach: volumes, colours, and styles are all planned ahead of each season, with stock warehoused until it can be sold.

Make-to-order (MTO) manufacturing process

Using the make-to-order (MTO) manufacturing process, manufacturers begin a production run when they receive a purchase order, creating just enough product to fulfil that request.

For that reason, it’s sometimes called pull production, with products being pulled through the production process by the customer’s order.

MTO manufacturers often sell higher-value goods, as well as products that are customised, rather than standardised. An aircraft manufacturer, for example, would only ever operate as an MTO business. Similarly, a dressmaker might use an MTO approach, ordering in fabric after a customer chooses the particular specifications that they want.

Make-to-assemble (MTA) manufacturing process

The MTA approach is a hybrid of the MTS and MTO systems.

In MTA all the required components are either created or purchased ahead of time, with the final product built quickly as an order is received. Some tailors, for example, will quickly create a bespoke suit for a client using panels of fabric that have been pre-cut and stitched, with only minor adjustments needed to assemble the final piece.

Similarly, some computer manufacturers allow clients to request custom-built machines to match their needs, adding RAM, and swapping out graphics cards as needed.

An MTA approach works well where a business needs the flexibility of customisation but wants to fulfil orders quickly. Finished goods that perish quickly are also well suited to being assembled to order.

How manufacturing works on the factory floor

There are countless ways to manufacture products entirely dependent on the raw materials and components being used, the type of goods being produced, and the personal preferences of key decision-makers within a given company.

However, we can break down how manufacturing production works in a large number of different business models by segmenting the most common production processes used around the world.

The 8 main manufacturing processes:

- Machining: Shaping and removing material from raw goods or components to create a desired finish.

- Joining: Connecting or assembling multiple items to form a single, unified product.

- Casting: Pouring liquid such as molten metal or alloy into a mould to create a solid object.

- Forming: Reshaping and transforming raw materials using mechanical or thermal methods.

- Moulding: Shaping a material by pouring or pressing it into a cavity, waiting for it to cool, and removing the outer casing.

- Assembly: Combining separate components or parts to create a finished product.

- Finishing: Treating an almost-finished product to enhance its appearance, usefulness, or quality – for example, painting, sanding, and varnishing.

Many goods manufacturers will use a combination of these processes to produce a single product. The ways in which they plan and implement a production process are known as manufacturing techniques.

Let’s look at some examples.

Manufacturing techniques

Here are some of the common tactics, or manufacturing techniques, that can be implemented to improve the efficiency of your production processes.

Discrete manufacturing

Discrete manufacturing is a technique used to build unique and distinct goods. This is a popular strategy for companies assembling products from individual parts or components – for example, computers and household furniture.

Discrete manufacturing processes largely rely on a bill of materials – a key document that functions as an ingredient list and recipe for producing a finished good.

Process manufacturing

Process manufacturing is where a manufacturer produces goods through a series of repeatable or sequential steps. It differs from discrete manufacturing in that process manufacturing builds products by transforming materials rather than assembling components.

Repetitive manufacturing

In repetitive manufacturing, similar or identical products are manufactured in large quantities using an automated production process. While this method leaves little room for customisations and variations, it’s a highly efficient way to produce a large number of alike goods.

Batch production

Batch production is where groups of identical products are created in production runs. For example, when a clothing range includes several different styles of jacket, each style will be produced at once, before the production line is reset to accommodate the needs of the next product – with sewing machines swapped out and pattern-cutters reprogrammed as needed.

Similarly, beer is produced in batches, with each batch needing different temperatures, time scales and ingredients, despite being produced with largely the same equipment.

Job shop manufacturing

Job production is where a single end product is completed before the next item is begun. The job production method naturally aligns with MTO manufacturing and is suited to creating high-value and unique items.

Custom jewellers, shipbuilders, and aircraft manufacturers all use the job production method.

Flow production

Flow production, also called continuous manufacturing, is where identical, standardised items are produced continuously and en masse in the name of optimal efficiency.

Often using conveyor belts to move products sequentially through the assembly process, flow production lines are often capital intensive, but with lower labour costs.

Flow production is suited to creating high volumes at a low price per unit, with limited and often lower-skilled labour required.

Just-in-time manufacturing

Just-in-time manufacturing is a production technique in which goods are produced based on customer demand, not in advance of need. It aims to increase efficiency and improve order fulfilment times while simultaneously minimising excess costs and waste within a company.

Lean manufacturing

Similar to the just-in-time approach, lean manufacturing is a technique that focuses on increasing efficiency by eliminating waste. The primary difference is that just-in-time manufacturing focuses on the business, while the main goal of lean manufacturing is to add value for the customer.

Lean manufacturing was made famous in the 1940s by Japanese car manufacturer, Toyota, based on Ford’s assembly flow production method.

Digital manufacturing

Digital manufacturing refers to the integration of computer systems and production lines. It embodies the modern approach to manufacturing, where technological advancements are harnessed for the sake of increased productivity and reduced costs.

A key function of digital manufacturing is that it allows manufacturers to integrate with the rest of their supply chains. As such, visibility over important information like lead times and delivery statuses is made more readily available.

Cloud manufacturing

Cloud manufacturing is a type of digital manufacturing technique that relies on cloud-based manufacturing systems such as inventory management software and bill of materials software.

In cloud-based manufacturing, data is stored on a cloud that can be accessed via the internet. It enables business owners to view live updates regarding their manufacturing processes and financial status.

Cloud tools benefit from their ability to integrate with one another, allowing manufacturers to create a single source of truth and a consistent flow of information within the business.

Mass production

The mass production method of manufacturing involves producing large quantities of standardised goods at a high rate, typically using assembly lines. By taking advantage of economies of scale, companies can produce sufficient quantities to meet consumer demand without driving the cost of production through the roof.

Mass customisation

Mass customisation is the child of mass production and MTO manufacturing. The technique allows companies to produce a broad range of product variations while remaining efficient and achieving economies of scale.

Contract manufacturing

Contract manufacturing is when one company designs a product and outsources the manufacturing of this product to another company.

Businesses use contract manufacturing when they do not have the assets—such as the facilities, equipment or skilled staff—to produce their goods in the quantity needed. By using a contract manufacturer, businesses can avoid having to make a large capital investment to produce their goods, and production can be scaled easily as the business grows (or shrinks).

Ultimately, the decision on whether to use a contract manufacturer will rest on whether it is cost-effective for the business, and what capabilities the company already has.

Toll manufacturing

Toll manufacturing – like contract manufacturing – involves an agreement between the client and the manufacturer. However, it differs in that the client provides the raw materials that the manufacturer then processes into goods to be sold.

For example, a supermarket may use a toll manufacturer to produce goods that are then house-branded before hitting the shelves.

Types of manufacturers: OEMs and ODMs

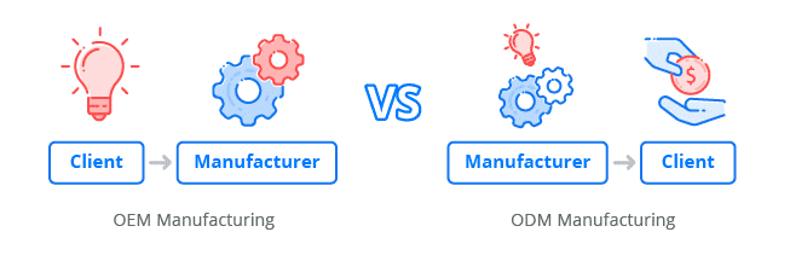

Original Equipment Manufacturers (OEMs) and Original Design Manufacturers (ODMs) are two common types of manufacturers.

Here’s the difference:

- OEMs produce items according to their clients’ design specifications.

- ODMs produce items according to their own design, which clients then buy and market.

Original equipment manufacturers (OEMs)

OEMs manufacture products that a client has developed and designed.

An OEM may also produce components that the client then uses in its own manufacturing process. While OEMs sometimes provide design advice, usually the client retains their intellectual property rights.

For clients, the potential benefits and downsides of using OEMs for manufacturing are substantially the same as for contract manufacturing. OEMs allow businesses to produce goods without a significant capital investment, such as acquiring new premises and staff.

A key benefit of being an OEM is that the manufacturer is not responsible for the design and testing of the product, which reduces their costs. In addition, OEMs’ premises and equipment will often not need to be upgraded to manufacture their clients’ goods – but where this is required, some of this cost can be passed on to the client.

On the other hand, a downside for OEMs is that the market is competitive, meaning you will have to differentiate yourself from other companies to grow your OEM business.

Original design manufacturers (ODMs)

ODMs are responsible for much more of the product design process than OEMs, and they retain their IP rights for their designs. A client will come up with a new idea for a product, and the ODM will undertake R&D, testing and design for the product.

ODMs sometimes design and produce items to be sold as white or private-label goods:

- White label: ODMs design and manufacture goods with a blank label which retailers then re-sell under their own brand – the ODM effectively leases out its products to the client.

- Private label: ODMs design and produce goods, and customise these for clients so they have an exclusive product to re-sell.

For a client, using an ODM means that products are designed and manufactured without R&D and other up-front investment. The flip side of this is that competitors may buy the same white-label product, meaning that consumers will be offered exactly the same product by different brands.

As an ODM, benefits include the fact that manufacturing is cost-effective and efficient since the ODM can choose the products it manufactures without needing to build its own brand. This may be further improved through automation and the use of manufacturing software.

On the other hand, setting up as an ODM can include high costs – including market research, R&D and product design.

Manufacturing and supply chain management

Manufacturing plays an important role in the supply chain. In some cases, it’s the first touchpoint for materials and parts that will eventually end up in a consumer’s hands.

Raw materials are delivered to manufacturers – or produced by them – and converted into products which are then sold to retailers, wholesalers, distributors, and in some cases, directly to the final customer.

In this last scenario, known as direct-to-consumer (D2C) manufacturing, the manufacturing supply chain has significantly fewer touchpoints. Goods are produced by the manufacturer and listed for sale on their website or via a catalogue, from which customers may place a direct order.

Manufacturing and inventory management

From the inventory perspective, manufacturing is the process of assembling a group of existing products under a new stock-keeping unit (SKU) code. In theory, this process should create more value than the sum of its parts.

It may also generate waste, which can be assigned a cost that can be tracked using various manufacturing accounting and costing methods.

There are four main types of manufacturing inventory:

- Raw materials

- Work-in-process goods

- Finished goods

- Maintenance, repair, and operations (MRO) inventory

Because so many manufacturers strive for maximum efficiency, inventory management is an important contributor to the overall success of a manufacturing business.

Good manufacturing practices

Good manufacturing practice (GMP) provides a set of rules and best practices for safe manufacturing in industries like pharmaceuticals and food and beverages.

GMP provides measures so that businesses maintain quality control, which ensures consumers are not harmed by faulty products. At the same time, GMP minimises the risk of manufacturers becoming liable for producing harmful products.

GMP applies to several industries that produce goods for human consumption:

- Food and beverages

- Cosmetics

- Pharmaceutical products

- Dietary supplements

- Medical devices

Businesses around the world go through a rigorous auditing and inspection process to receive GMP certification. Many countries will not allow the importation of goods in certain industries without this certification.

The Five Ps of GMP summarises the principles behind GMP:

- People: Do your staff receive adequate and up-to-date training?

- Premises (and equipment): Are these maintained, calibrated and cleaned to prevent problems like cross-contamination?

- Products (and materials): Are all items in your facility—primary materials, components, products—handled correctly throughout the manufacturing process?

- Processes: Are your processes documented clearly and consistently?

- Procedures: Do these provide detailed, step-by-step instructions for each of your processes?

GMP authorities around the world

Different countries have their own regulatory agencies to certify compliance with GMP. In the US, for instance, the Food & Drug Administration (FDA) is responsible for GMP regulation, while in the UK the Medicines and Healthcare Products Regulatory Agency (MHRA) performs GMP inspections.

Manufacturing systems

A manufacturing system can mean either an accumulation of a company’s various manufacturing technology, processes, and actions used to create finished productions or simply a singular tool – such as manufacturing software – that’s used to manage production.

Manufacturing software

Manufacturing software is a digital system that helps to automate or simplify various processes involved in production, from demand planning and accounting right through to the physical production and customisation of products.

Common types of manufacturing software include:

- Manufacturing accounting software

- Cost-estimating software

- Manufacturing inventory management software

- Computer-aided design (CAD) software

- Production planning software

Each of these tools – and many more – exist to make manufacturers’ lives easier.

If you’re looking for ways to streamline your manufacturing operations and increase efficiency, manufacturing software is an excellent place to start.

- Shopping for a new manufacturing system? Check out our Best Manufacturing Software Guide