Work in process (WIP) inventory is typically found in manufacturing environments where goods undergo various stages of processing before being sold or used. Tracking WIP inventory is important for monitoring production efficiency, identifying bottlenecks, and managing costs within the manufacturing process.

This guide covers the work in process inventory formula, how to calculate it, and how to cost-effectively manage your work in process inventory.

What is work in process (WIP) inventory?

Work in progress (WIP) inventory refers to partially completed goods or products still in the production process that have not yet reached the final stage of completion. It represents the value of materials, labour, and overhead costs incurred in the production process but not yet transferred to finished goods inventory.

Imagine you're making a pizza from scratch. You've got your dough rolled out, put some sauce on it, and spread a sprinkle of cheese. But it's not quite done yet – you still need to add additional toppings and pop it in the oven. That almost-finished pizza is an example of work in process inventory.

In business terms, WIP inventory is goods that are in the process of being made but aren't ready for sale yet.

Why WIP inventory management is important

There are three main types of inventory in manufacturing: raw materials, WIP inventory, and finished goods.

Of these, WIP inventory is often the most overlooked.

However, keeping tabs on your WIP inventory has major benefits. You’ll gain a more accurate value of your business, spot potential bottlenecks early, and avoid hand counting of your inventory.

Accurate WIP inventory management also facilitates better financial reporting – helping you to meet your legal obligations and maintain healthy cash flow.

What’s the difference between work in process and work in progress?

While similar in context, there are a few subtle differences between work in process and work in progress.

Work in process is typically used by the manufacturing sector to account for goods that are only incomplete for a short period. These products are neither raw materials nor finished goods but are still assets (with value attached) for the company. Keeping track of work in process is critical for financial reporting.

Work in progress, on the other hand, usually refers to larger, more complex projects. For example, the construction industry will use work in progress when building a house. Work in progress inventory is typically ‘in progress’ for a lot longer than work in process goods, sometimes spanning several accounting periods.

Work in process inventory example

As an example of how work in process inventory works, imagine you have a furniture manufacturing company.

An order comes in for a wooden dining table. At different stages of production, various pieces of the table are coming together. You have the legs carved out, the tabletop sanded and smoothed, and the varnish or paint applied.

Each of these components – the unfinished legs, tabletops, and other components – is stacked up in your warehouse or factory, waiting for the next step in the process.

A complete dining table ready to be packaged and shipped to the customer does not yet exist. Therefore, these parts are classified as work in process inventory until the assembly has finished.

How to calculate work in process inventory

Before you can calculate your work in progress (WIP) inventory, you need to identify three key metrics:

- Beginning WIP inventory costs: Also known as opening inventory, this refers to the expenses associated with materials, labour, and overheads* that were already spent in the production process at the beginning of a specific accounting period. These costs represent the unfinished products or partially completed work from the previous period.

- *Overhead costs are indirect costs that cannot be directly attributed to specific units of production but are necessary for the manufacturing process. This could include expenses like utilities, rent for the production facility, or equipment depreciation.

- Manufacturing costs incurred: These are the expenses accrued during the current accounting period for producing goods, including raw materials, wages for labour, and manufacturing overheads.

- Cost of goods manufactured (COGM): This is the total cost of producing finished goods during a specific accounting period. It includes the beginning work in process inventory costs and any manufacturing costs incurred during the period and subtracts the ending work in process inventory costs to determine the total cost of goods completed and ready for sale.

The accuracy of these calculations depends on how well you track and allocate costs throughout the production process. 77% of organisations have reported lost revenue due to data issues. That’s why it’s crucial to have a good understanding of your manufacturing costs and accounting practices: it ensures your WIP inventory is correctly represented.

Once you’ve got your figures the metrics above, you can calculate your WIP inventory value using the WIP inventory formula.

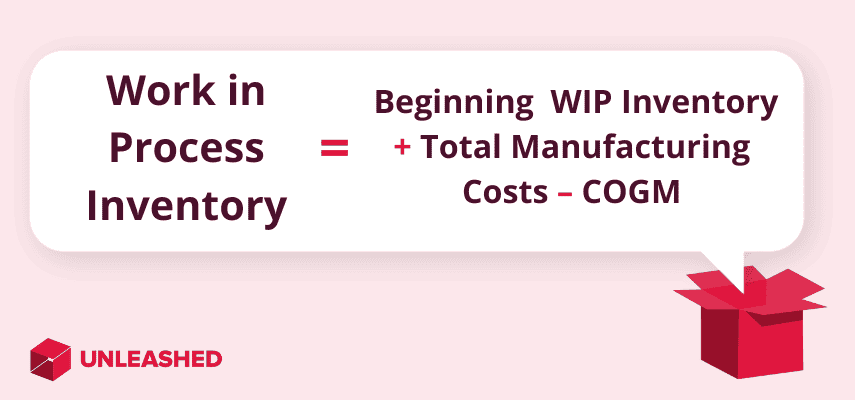

Work in process inventory formula

The work in process inventory formula helps calculate the value of inventory that is still in the production process and not yet completed.

To calculate the ending WIP inventory, you need to consider the value of the work in process inventory at the end of the current period. This figure represents the unfinished goods or products that are still in the production process but haven't been completed by the end of the period you're looking at.

Here's the WIP inventory formula:

Beginning WIP Inventory + Manufacturing Costs Incurred - Cost of Goods Manufactured = Ending WIP inventory

By using this formula, you can determine the value of inventory still in progress at the end of the accounting period to assess production progress, manage inventory levels, and accurately reflect the value of goods in various stages of completion.

Beginning work in process inventory formula

The beginning work in process (WIP) inventory formula is a simple way to assess how much unfinished inventory you have at the start of a given period.

To calculate the beginning WIP inventory, take the value of the work in progress inventory from the previous period. These are the unfinished goods or products that were already in the production process but not yet completed by the end of the previous period.

If you're starting a new accounting period and you want to know how much WIP inventory you're carrying over from the previous period, you use the beginning WIP inventory formula:

Beginning WIP Inventory = Ending WIP Inventory from Previous Period

It's a way to keep track of the unfinished work from one period to the next, giving you a starting point for assessing your production efficiency and managing your inventory levels.

Example of work in process inventory formula

Let’s say your furniture company’s beginning WIP is $20,000.

During the new accounting period, you spend $80,000 on manufacturing your furniture. The total cost for your finished goods is $90,000.

Using the WIP inventory formula, you would calculate your ending WIP like this:

$20,000 + $80,000 - $90,000 = $10,000

WIP inventory accounting

WIP inventory accounting is the process of tracking and managing the value of partially completed goods or products in a manufacturing or production environment. It involves recording and monitoring the costs associated with the production process, from the raw materials stage to the completion of goods.

In WIP inventory accounting, various costs are tracked, including the cost of raw materials, direct labour, and manufacturing overhead such as utilities and depreciation of equipment. These costs are accumulated as goods move through different stages of production.

Keeping track of WIP inventory involves maintaining accurate records of the costs incurred at each stage of production and updating these records as goods move closer to completion.

WIP inventory accounting plays an important role in ensuring the accuracy of financial statements – including the balance sheet and income statement – by properly reflecting the value of inventory at various stages of production.

Work in process inventory accounting is essential for understanding your profit margins and cash flow.

Work in process inventory accounting is essential for understanding your profit margins and cash flow.

How to cost-effectively manage your work in process inventory

Managing WIP inventory cost-effectively can be achieved by implementing one or more of the following strategies. These methods can be utilised in most manufacturing environments.

1. Tighten up your production processes

Analyse the production workflow to identify inefficiencies or unnecessary steps. Look for any opportunities to increase productivity with better technology, new equipment, or more staff. Streamlining processes can help reduce the time and resources required to complete each stage of production, thereby minimising WIP inventory buildup.

2. Implement Just-in-Time (JIT) manufacturing

JIT manufacturing aims to minimise WIP inventory by producing goods only as needed, in response to customer demand. By synchronising production with demand, you can reduce excess inventory holding costs and minimise the risk of obsolete inventory.

3. Create realistic production schedules

Establishing achievable production schedules helps prevent overproduction and excessive WIP inventory accumulation. Use an MRP system, inventory management software, or ERP software to align production plans with demand forecasts, capacity constraints, and lead times. This can help optimise resource utilisation and minimise inventory levels.

4. Track inventory levels in real time

Regularly monitor WIP inventory levels to identify trends, fluctuations, or excessive buildup. Implement cloud-based inventory tracking software and visual management techniques to provide real-time visibility into inventory status and facilitate timely decision-making.

5. Optimise workforce utilisation

Ensure that labour resources are effectively optimised to minimise idle time and maximise productivity. Cross-train employees to perform multiple tasks and adjust staffing levels based on production demands to maintain an optimal balance between labour and production capacity.

6. Follow lean manufacturing principles

Adopting lean manufacturing principles, such as continuous improvement, waste reduction, and value stream mapping, can help eliminate non-value-added activities and optimise production processes. By focusing on efficiency and eliminating waste, businesses can reduce WIP inventory levels while improving overall operational performance.

7. Collaborate with your suppliers

Collaborate closely with suppliers to establish reliable supply chains and minimise lead times for raw materials and components. Implement vendor-managed inventory (VMI) or just-in-time delivery arrangements to ensure timely replenishment of materials, thereby reducing the need for excess WIP inventory.

8. Invest in manufacturing automation

Leverage automated technology solutions – such as inventory management software, production planning systems, and automation technologies – to streamline processes, improve visibility, and enhance decision-making capabilities. Automation can help reduce manual errors, improve process efficiency, and enable real-time monitoring of production activities.

Modern technology solutions such as cloud manufacturing software help automate WIP inventory management.

Modern technology solutions such as cloud manufacturing software help automate WIP inventory management.

Accurately record all your manufacturing costs in real time

To guarantee accurate WIP inventory accounting, you need to correctly record all the costs associated with manufacturing your products. Done manually, this can consume a lot of your precious time – while increasing your risk of errors or miscalculations.

Unleashed manufacturing inventory software automatically tracks and records all your production costs as they occur, along with crucial sales and inventory data. It allows you to manage your entire business on the cloud while streamlining all your production and stock control processes.

If you’re ready to optimise your manufacturing inventory and boost productivity, consider these next steps:

1. Watch a manufacturing software demo. Discover how cloud-based manufacturing software helps you boost financial visibility and WIP inventory accuracy across the business, saving you hours of admin time and reducing your operational costs.

2. Sign up for a free 14-day trial of Unleashed. See first-hand the ways manufacturing inventory software can help you maintain healthy cash flow and optimise production processes with a risk-free two-week trial of Unleashed.

3. Chat with a manufacturing inventory expert to assess your needs. If you’re looking for guidance as to the next step for optimising your production management processes, book a free chat with one of our friendly experts for an honest discussion about how you could be better managing your inventory.