A warehouse management system (WMS) is a powerful software tool that can help improve warehouse efficiency and reduce the cost of managing warehouse inventory. WMS solutions are designed to optimise how a storage facility operates – from capacity utilisation to stock control – while making staff more productive.

This guide will teach you everything you need to know about warehouse management systems, including how they work, the different types of warehouse software, and key features to look for.

What is a warehouse management system?

A warehouse management system (WMS) is a type of software that helps businesses control and improve the efficiency of operations within a warehouse environment. WMS solutions provide real-time visibility across a company’s inventory levels, from when goods are received in the warehouse to the time they’re shipped off to customers.

Warehouse management systems aim to streamline and optimise the daily running of a warehouse or distribution centre. By tracking and managing daily warehouse tasks, a WMS enables businesses to standardise processes and monitor inventory management efficiency more easily.

Warehouse management system vs inventory management software

Warehouse management systems and inventory management systems are similar software tools with nuanced differences that make them better suited to certain applications.

Inventory management software is primarily concerned with the movement of inventory in a business.

Like a WMS, inventory software offers real-time tracking of stock levels, optimisation of inventory control processes, and accurate inventory reporting. However, inventory systems go a step further to assist with all stages of a product’s lifecycle by providing powerful tools for managing procurement, production, and sales.

Conversely, warehouse management systems have a greater focus on optimising a warehouse or distribution centre.

While this usually includes some useful inventory management functionality, WMS solutions dive deeper into the operational aspects of a company – with features designed to improve warehouse layouts, optimise storage efficiency and labour utilisation, and streamline the order fulfilment process.

This table summarises the unique functions of WMS vs inventory software:

Warehouse Management Systems |

Inventory Management Systems |

|---|---|

|

Inventory management and stock optimisation |

|

|

Storage capacity utilisation |

Purchase order management |

|

Order fulfilment and shipping processes |

End-to-end supply chain management |

|

Warehouse layout optimisation |

Production planning |

|

Labour and productivity management |

Inventory accounting and reporting |

|

Task scheduling and workforce optimisation |

Multichannel order management |

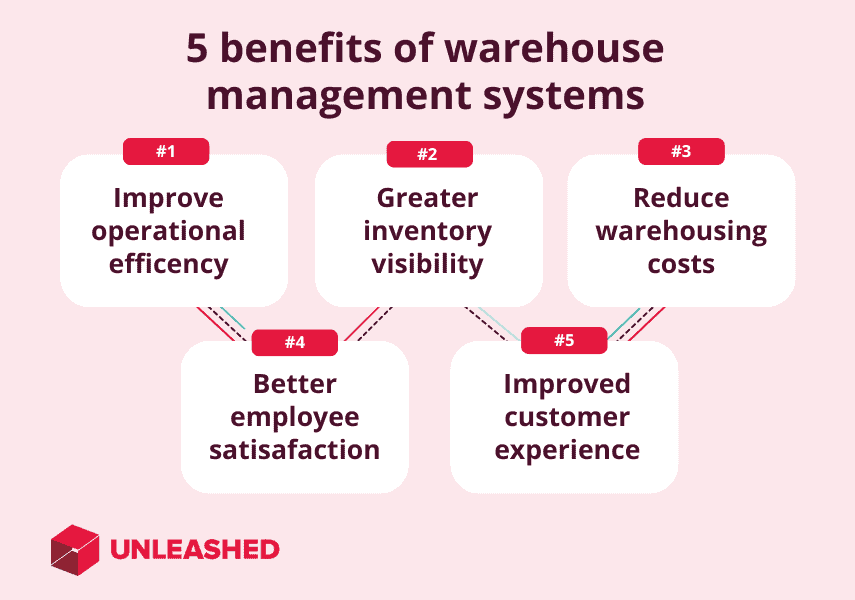

5 benefits of a warehouse management system

A warehouse management system is designed to optimise various warehouse processes to reduce operational costs and increase the productivity of warehouse teams. Here are the main benefits of WMS software.

1. Improved efficiency

WMS software offers efficiency gains by improving warehouse layouts, optimising labour and equipment usage, and enabling real-time inventory tracking. This results in jobs getting done faster and more accurately, ultimately increasing productivity and profitability.

2. Greater visibility

Real-time inventory tracking ensures you always have an accurate digital database of everything in stock – where it is, where it’s going, and how many units are currently available in the warehouse. A WMS helps you make the right decisions around inventory replenishment and marketing, and better utilise storage locations to reduce labour time.

3. Reduced business costs

With improved efficiency and productivity, a WMS can also bring your total business costs down. Decreased travel times through warehouse layout optimisation reduces the labour costs of managing your warehouse, while inventory storage optimisation reduces the costs of order fulfilment.

Warehouse management software also improves inventory accuracy, reducing your inventory carrying costs and improving cash flow. All of these financial gains ultimately result in a more profitable operation.

4. Increased staff satisfaction

Efficient warehouse systems make it easier to perform various warehouse roles. Employees can experience increased job satisfaction knowing they’re performing their functions in the easiest, most effective way possible.

An example of this is implementing a WMS with barcode inventory system functionality. Rather than manually writing down details from an item docket and then entering that information into a spreadsheet, a warehouse worker can simply run a laser over the barcode – ensuring accuracy and saving hours every week.

5. Happier customers

Warehouse systems improve order fulfilment speed and picking accuracy. This means customers receive goods faster, with a reduced risk of getting the wrong item or quantity. Real-time inventory updates also mean retailers can be sure of what’s in stock and avoid accidentally selling something unavailable because the system is out of date.

The main challenges of warehouse management systems

A warehouse management system is a large investment. It’s a software tool with comprehensive functionality – and therefore, a lot of room for expensive mistakes.

Some of the main challenges to be aware of when implementing a WMS include:

- Insufficient planning: Migrating to a new WMS is usually a large project that requires significant planning to get right. Time and budget must be allowed for migration, configuration, testing, and training. This process can take weeks or months. If staff are not trained properly, the benefits of the tool may not be fully utilised, impacting the profitability of your investment.

- Integration challenges: To work most effectively, WMS needs to cooperate with your other systems. If supplier data, sales orders, and finance are connected to your warehouse software, it’ll improve the accuracy of your digital records. However, not all software is directly compatible, which can require custom APIs and additional administrative work.

- Lack of ownership: For a WMS implementation to go smoothly, someone needs to ‘own’ the system and its training processes. There must be procedures in place to encourage best-practice installment and usage, and your warehouse may need new codes or hardware.

- Resistance to change: Change management is critical with any system upgrade. Staff are likely used to working a certain way – asking them to alter their workflows may cause friction if poorly communicated. Remember to always communicate the benefits of the new system and ensure sufficient time for training is provided.

- Vendor procurement: There is more than one type of WMS on the market and they won’t all be right for your business. Factors like size, budget, expected growth, and unique requirements can affect which type of WMS is right for you, so ensure thorough time and consideration are given to software procurement.

Warehouse management system features

There are a range of warehouse management systems available on the market. Some of these offer industry-specific functionality, such as manufacturing automation, while others are more generalised. When shopping for warehouse software, make a list of all the features essential to solving the specific needs of your organisation.

Some common WMS features include:

- Warehouse management

- Barcode scanning

- RFID scanning

- Shipping management

- Inventory control

- Quality management

- Automatic label printing

- Kitting

- Warehouse layout optimisation

- Task scheduling

- Employee productivity tracking

- Returns management

- Storage utilisation control

- Yard and dock management

- Data analysis and reporting

You might not need every single feature listed above – or you might need all that and then some – so be wary of investing in warehouse software that is too simple or too complex for your needs.

Types of warehouse management systems

Warehouse management systems come in a variety of types, and there’s no one-size-fits-all approach that works for everyone. Understanding what might be best for you (and your budget) is critical to ensuring you maximise your investment.

1. Traditional WMS (paper- or spreadsheet-based systems)

Traditional WMS – also known as legacy systems – use paperwork and spreadsheets to manage inventory, customer orders, and labour. Traditional warehouse systems are still in frequent use around the world. According to a report by Zebra, 11% of warehouses still use all-manual processes.

That same report also found that the biggest challenges faced by warehouse teams globally included labour efficiency, capacity utilisation, and data quality – all of which are vastly improved by non-legacy systems, such as warehouse inventory management software.

While manual processes can suffice for simple or small operations, an automated solution typically becomes essential as the business grows in size or complexity.

2. On-premise WMS

An on-premise WMS is a standalone system installed into local hardware at your warehouse. It is operated by your team and can be customised to suit your unique business needs.

Standalone WMS systems typically have higher initial costs and may require additional maintenance or hardware costs as updates become available. The benefit of an on-premise solution is that it can be customised specifically to your needs and doesn’t require sharing any data externally.

3. Cloud-based warehouse software

Cloud-based warehouse systems are a software-as-a-service (SaaS) product, whereby the company purchases a licence to use software hosted elsewhere and accessed through the internet.

Cloud-based systems, including WMS, typically use either browser-based dashboards or apps, making them convenient to use and often quick to learn. They can also be accessed anywhere, on any device, making it easy to view and update vital warehouse information no matter where you’re located (enabling some staff to work from home).

The lack of extra installation costs or ongoing maintenance also makes it a cost-effective solution. Cloud-hosted software typically integrates well with other systems.

4. Integrated WMS

Another type of warehouse management system is an integrated module that acts as a feature of a larger suite of tools. These integrated solutions include enterprise resource planning (ERP) software, supply chain management software, or inventory management software.

WMS within ERP

ERP systems are multifunctional business software tools designed to help organisations manage, monitor, and optimise workflows across multiple departments of a company – such as manufacturing, finance, and human resources.

In an ERP system, a WMS module can provide warehouse management functionality that helps improve efficiency by sharing data in real time across key areas of the organisation.

ERP systems can be expensive and time-consuming to implement and typically come with a higher subscription cost. Their dynamic functionality, however, makes them useful for larger businesses with complex needs.

WMS within supply chain management software

Supply chain management (SCM) software is designed to help control the various processes related to the movement of goods through a supply chain. It typically provides procurement, logistics, fleet management, supplier relationship management, and inventory control features.

Many SCM platforms come built-in with a WMS function. While it may not have the same functionality as a dedicated WMS system, its integration with other workflows can save time and help improve supply chain visibility and performance.

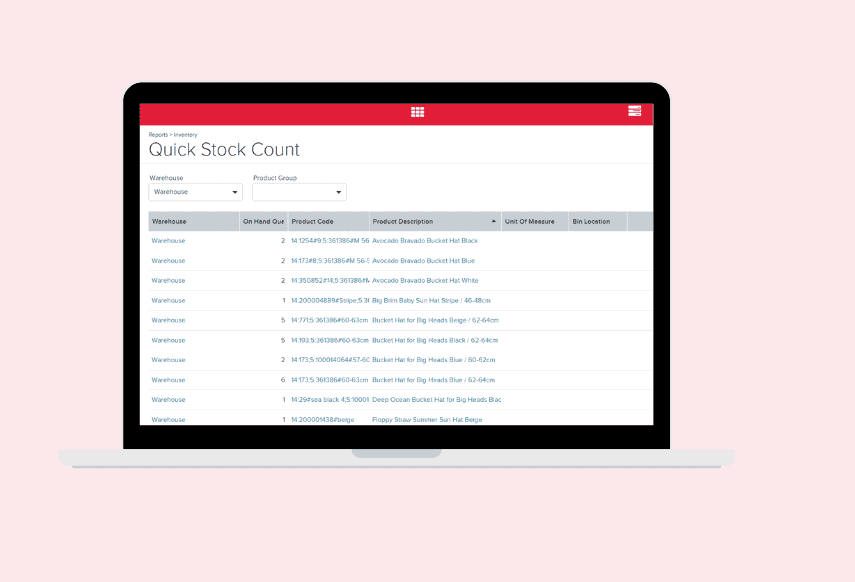

WMS within inventory management software

Because of the large overlap, warehouse management optimisation is often a component of cloud-based inventory software. Depending on the needs of customers, many inventory solutions evolve to include key WMS features.

Modern inventory management software typically shares the following features with WMS:

- Cloud-based stock control

- Order management

- Barcode scanning

- Multiple warehouse inventory management

- Returns management

- Order fulfilment

- Product identification

- Reporting and analytics dashboards

Who are warehouse management systems best for?

If your organisation deals with physical inventory that is stored in a warehouse or distribution centre, you may benefit from a warehouse management system. This is especially true if you operate a large or growing enterprise, or are experiencing significant issues related to productivity and stock accuracy.

Signs you might need a warehouse management system:

- Your business is growing fast

- Your inventory levels are frequently inaccurate

- You operate a high-volume product business

- You need to increase productivity or reduce operational costs

- You operate multiple warehouses

- Your inventory is sensitive or perishable

- You manage inventory on behalf of other businesses

Do small businesses need a WMS?

Many small businesses may find a warehouse management system too expensive or feature-rich for their requirements. However, as a company’s inventory grows, warehouse software can quickly become a necessity for ensuring maximum productivity and profitability.

Speak to a software expert or business advisor who understands your business to find out if it’s the right time to upgrade to a more organised warehouse management solution.