Sustainable manufacturing is about product creation that doesn’t deplete natural resources or harm the environment.

It’s a blend of innovative technologies and eco-friendly practices that companies might implement, including the use of renewable energy sources, recycled materials, and more durable product designs which are easier to repair.

Implementing sustainable practices in your manufacturing operations not only protects valuable resources but can lead to financial savings and increased brand reputation. Therefore, embracing sustainability, while good for the planet, is also a smart business strategy that can lead you to long-term success.

What is sustainable manufacturing?

Sustainable manufacturing is an inventive approach to manufacturing that aims to reduce the negative environmental impact of production operations while maximising resource efficiency within your industry.

By implementing sustainable manufacturing strategies, manufacturers can significantly reduce environmental impact. These include waste reduction, responsible raw material usage, energy efficiency, and renewable energy alternatives.

Sustainable manufacturing is a forward-thinking process that aligns with global efforts to ensure a healthier planet for future generations. Strategies benefit both the environment and a manufacturer's social and economic bearing.

The Organisation for Economic Co-operation and Development (OECD) provides a sustainable manufacturing toolkit to help businesses implement sustainable practices. The seven-step guide helps manufacturers improve the efficiency of their production processes while emphasising the importance of green growth.

By following these guidelines, manufacturers can contribute to a more sustainable future while benefiting from the economic opportunities that come with it.

A fundamental aspect of sustainable manufacturing is the usage of environmentally responsible materials.

A fundamental aspect of sustainable manufacturing is the usage of environmentally responsible materials.

Lean manufacturing and sustainability: A brief history

Lean manufacturing is a tactic to minimise waste and efficiency maximisation that was developed by the Toyota Motor Corporation in the mid-twentieth century.

The lean approach was invented – in part – to incorporate environmental sustainability with research suggesting that lean manufacturing through waste reduction, less resource consumption, and improved operational efficiencies could align with environmental goals to reduce manufacturing’s environmental footprint.

However, aligning the two is not without its challenges. Trade-offs become necessary when the cost-saving measures of lean practices conflict with environmental and social interests.

For example, the pursuit of lean efficiency is positive for the environment when it leads to reduced material use and energy consumption, but might also result in a reduced workforce, which can have negative social and economic implications. Lean’s just-in-time production can improve efficiency and reduce waste through the aligning of production schedules with demand, yet it often requires more frequent transportation of goods, which can lead to increased carbon emissions and a negative environmental impact.

More recently, the principles of lean manufacturing – while still focused on production efficiency – have evolved to incorporate more sustainable manufacturing practices and address the contemporary challenges of environmental, social, and economic factors. The integration of both intends to reflect a broader understanding of sustainability beyond environmental concerns alone and incorporates both the social and economic aspects.

This systematic approach known as Corporate Social Responsibility (CSR) has gained traction as a pivotal business strategy in the past 20 years, particularly as a response to scandals and increased scrutiny of unethical corporate practices.

Why sustainable manufacturing is important

In the modern marketplace, customers are increasingly seeking out businesses that prioritise sustainability – not just in environmental terms, but also in cultural and social aspects.

This shift reflects a growing awareness of the interconnectedness of business practices and global challenges such as climate change, resource depletion, and social inequality.

Sustainable business practices are defined as actions that allow a company to create a positive impact on people, society, and the environment while also making a profit. These practices balance the three pillars of sustainability – environmental, social, and economic – focusing on waste reduction, conserving resources, and improving efficiency and profitability.

An example of this is the current trend in which companies are increasingly turning to renewable energy sources, implementing recycling programs, engaging in ethical sourcing, and managing sustainable supply chains.

These efforts not only help protect the environment and the people who live in it, but also offer financial benefits through cost savings, waste reduction, and conserving natural resources.

How sustainable manufacturing evolves a business

The evolution of sustainable business practices can be seen in the progression from traditional management focused solely on economic growth to a more holistic approach that includes social and environmental considerations.

This evolution is marked by three levels of sustainability in business:

- Focusing on refined shareholder value management.

- Balancing the three sustainability balance sheets.

- A proactive approach to solving the world's sustainability problems.

From a social aspect, businesses are also encouraged to partner with nonprofit organisations, educate their employees about sustainability, promote volunteerism, and measure the impact of their sustainable practices. In doing so, they not only adhere to the principles of CSR but also align their operations with the values of customers who are increasingly looking to support responsible stewards of the environment and society.

This alignment is not just ethically sound but also strategically smart, as it can lead to a competitive advantage in a market where consumers are more conscious of where and how they spend their money.

Benefits of sustainable production for manufacturers

Sustainable manufacturing practices offer a multitude of benefits for producers, which extend beyond environmental advantages to include economic and social gains. These include:

Reduced environmental impact

Through adopting sustainable methods, manufacturers can significantly reduce their environmental footprint and minimise waste and pollution while conserving energy and natural resources. This approach aligns with global efforts to combat climate change and meets the growing consumer demand for environmentally responsible products, providing a competitive edge in the market.

Reduced business costs

Sustainable manufacturing also leads to cost savings through more efficient use of materials and energy, as well as reducing the need for handling and disposing of hazardous waste. The integration of sustainable practices often drives innovation, leading to the development of new, greener products and processes that can open greater market opportunities.

Regulatory compliance

From a regulatory standpoint, sustainable manufacturing can help companies stay ahead of increasingly stringent environmental laws, avoiding potential fines and legal issues. Sustainable manufacturing also enhances the brand image and reputation of your business, which is a valuable attribute in today's socially conscious market.

Improved staff satisfaction

Sustainable manufacturing processes contribute to the health, safety, and well-being of workers by reducing exposure to harmful substances and creating a safer work environment. This can improve your employee morale and manufacturing productivity, and reduce costs associated with healthcare and absenteeism.

A more sustainable manufacturing industry

Sustainability in manufacturing helps contribute to the economic stability of communities by creating green jobs and supporting local economies. It also works to preserve the environment for future generations, ensuring the long-term viability of manufacturing activities.

Improving sustainability in manufacturing operations offers significant benefits both internally and socially.

Improving sustainability in manufacturing operations offers significant benefits both internally and socially.

Global sustainable manufacturing benefits

Sustainable manufacturing integrates environmental health, social equity, and economic viability to ensure a more efficient and responsible production process. The benefits of manufacturing sustainability are both diverse and crucial for the future of global industry.

Global sustainable manufacturing benefits include:

- A significant reduction in negative environmental impact by minimising waste and pollution, conserving natural resources, and reducing carbon footprints.

- Greater innovation, as manufacturers are compelled to find new raw materials and processes that align with their sustainability goals.

- Improved worker safety and satisfaction through the promotion of healthier workplace environments.

- Energy savings, as they often involve the implementation of more efficient technologies.

- Economic development of communities through the creation of jobs and fostering local industries.

These benefits demonstrate that sustainable manufacturing is not just an ethical choice but a strategic and economic one that can lead to long-term success and sustainability for businesses and the planet alike.

How to make manufacturing more sustainable: Key processes

Sustainable manufacturing is a dynamic process that involves a series of steps, outlined by the OCED which is designed to minimise your environmental impact while maximising your efficiency and productivity.

This seven-step process is not linear but should be viewed as part of a cyclical management process that emphasises continuous learning, innovation, and improvement. Here are the steps:

1. Map impact and set priorities

A sustainability team is tasked to set objectives and review environmental impacts to identify and decide sustainable priorities. The team is responsible for mapping the impact of your operations on the environment and setting clear priorities to help address these.

Through a revision of your business activities, the team can then identify key areas to determine any changes that can be made to produce the most significant difference. Setting objectives is crucial because it provides you with a direction and measurable targets for you to work towards.

This process not only helps to minimise any negative environmental impacts but also positions you as a responsible manufacturer with a reputation committed to sustainable practices.

2. Set performance indicators

Identifying and establishing key performance indicators (KPIs) relevant to your manufacturing operations will help you determine what data you should be collecting.

KPIs are crucial for assessing the efficiency and success of your operations. They provide measurable values that help guide your performance toward more sustainable operations and identify the areas you need to focus on for continuous improvement.

By monitoring KPIs, your operations manager can make more informed decisions to enhance your productivity, quality, customer satisfaction, and waste reduction.

3. Measure production inputs

Understand how the materials and components you use in production can influence your environmental performance.

Consider the entire lifecycle of material input, from raw materials to the finished product, and measure your production inputs with the corresponding emissions from material production and energy consumption during every stage.

Look for ways to mitigate these impacts and better reduce your carbon footprint with actions like optimising energy usage through renewable sources such as solar or wind power.

4. Assess operations

Evaluate the impact and efficiency of your manufacturing facilities, including energy intensity and emissions, to identify areas for improvement. Effective energy management in facilities not only improves sustainability and minimises your environmental impact but also produces cost savings.

The National Australian Built Environment Rating System has been instrumental in driving energy efficiency in commercial buildings, leading to significant reductions in energy consumption and greenhouse gas emissions.

By implementing strategic energy management practices, you can set benchmarks, track progress, and improve your energy consumption and operational efficiency, to contribute to a greener future.

5. Evaluate products

When evaluating your products for sustainability, it's crucial to consider several key factors that impact both the environment and CSR. Consider aspects like:

- Energy consumption: The products that require less energy throughout their lifecycle are generally more sustainable.

- Recyclability: This determines the potential for materials to be reused and reduces waste.

- Hazardous substances: These can pose risks during manufacturing, usage, and disposal.

By assessing products that are safe and sustainable by design, manufacturers and consumers can make more informed choices that support a sustainable future.

6. Understand measured outcomes

Interpreting KPIs to understand the relationship between these metrics and performance trends is essential to identify areas of success, pinpoint potential improvements, and make informed decisions to drive future growth and efficiency.

KPIs are classified into two categories:

- Leading indicators – Proactive measures that can predict future performance and help you make adjustments before outcomes are finalised.

- Lagging indicators – These provide data after an activity is completed and are useful for confirming long-term trends.

To effectively interpret these indicators, it’s important to consider the context of the data, compare it with historical performance, and recognise the factors influencing the results.

7. Improve performance

Identify opportunities for improvement and create action plans to implement them.

To improve organisational performance, a strategic approach is required to identify areas such as processes, technologies, employee skills, or even management practices ready for improvement.

The next step is to create detailed action plans that outline specific steps, allocate resources, set timelines, and establish metrics for success. It’s crucial to involve team members in the planning process to ensure buy-in and to leverage their on-the-job insights.

Regularly review and adjust action plans to ensure that the improvement efforts are on track and adaptable to any changes in the organisation's environment or objectives.

Sustainable production methods are benefit the environment and the manufacturer by reducing energy consumption and waste.

Sustainable production methods are benefit the environment and the manufacturer by reducing energy consumption and waste.

Tools for achieving sustainability in manufacturing

Digital transformation plays a crucial role in assisting manufacturers to achieve greater sustainability in their operations. Tools for achieving sustainability in manufacturing help to drive more workable manufacturing practices and solutions to reduce material waste and energy consumption, contributing to a lower carbon footprint.

Moreover, digital transformation fosters a culture of innovation, empowering employees through upskilling and creating new opportunities for cross-functional collaboration. As a result, you can realise improvements in labour productivity, forecast accuracy, and customer service, ultimately enhancing your competitive edge in the market.

Manufacturing sustainability metrics

Developing manufacturing sustainability metrics is crucial for assessing and guiding your business towards more environmentally responsible practices. Sustainability metrics measure your company's impact on the natural environment, including carbon footprint, energy efficiency, waste reduction, and water usage.

A McKinsey report highlights the importance of integrating sustainability with profitability and emphasises the role of manufacturers in leading the way towards a greener future.

The OECD has quantitative sustainable manufacturing indicators for environmental performance of inputs, operations and products to help decision-making, improve regulatory compliance and promote proactive contributions to a sustainable economy.

Sustainable manufacturing examples

Sustainable manufacturing is critical to contemporary manufacturing. Consumers' expectations increasingly dictate that modern industry practices minimise their environmental impact while maintaining economic growth and social responsibility.

Companies across a variety of industries are embracing a sustainable approach, and are implementing innovative strategies to reduce waste, conserve energy, and utilise renewable resources.

Examples of sustainable manufacturing include:

- Gairdin specialises in sustainable gardening tools and pots, using recycled materials like ocean-bound plastics and algae-blended resin to create environmentally friendly products.

- Electrolux's Kinston Plant significantly reduced energy consumption through its Green Spirit program, which includes measures such as optimising equipment usage and installing motion sensors for lighting.

- Advanced Composite Structure with their streamlined production processes, to eliminate excess raw material usage and increase efficiency.

- Unilever focuses on water conservation, sustainable regenerative and ethical sourcing.

- Fujitsu smart manufacturing solutions are transforming their factories into sustainable operations.

- BMW set ambitious CO2 reduction targets, and integrated sustainability into its entire production chain, from resource-efficient factories to electric vehicle development.

These companies not only adhere to sustainable manufacturing principles but also serve as benchmarks for others in the industry. They are demonstrating that profitability and environmental stewardship can coexist and provide a blueprint for future-oriented sustainable business practices.

Improving sustainability with cloud manufacturing software

A core aspect of achieving sustainability in manufacturing is the reduction of waste. This pertains not only to materials waste but also to wasteful activities that result in excess equipment usage and unnecessary downtime.

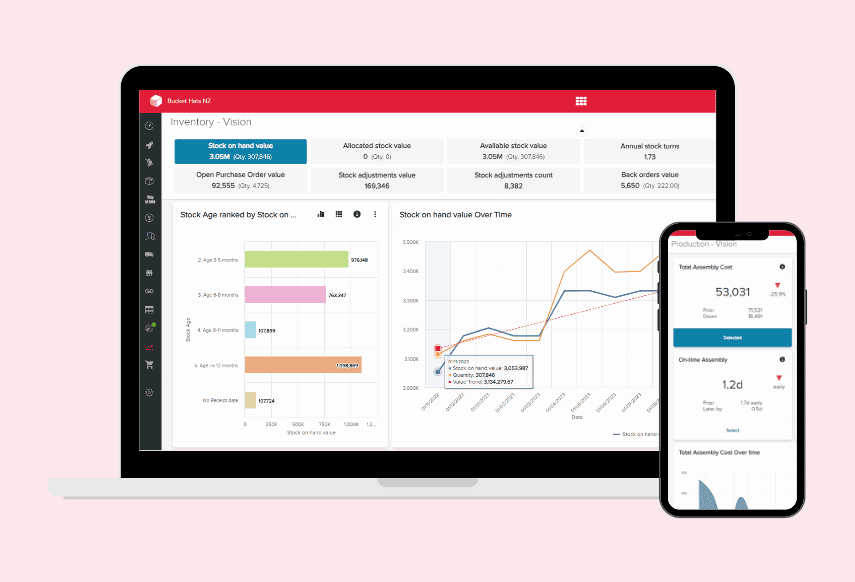

Unleashed is a cloud manufacturing software solution designed to maximise efficiency in your production operations. It helps you save time and money while reducing your environmental footprint by streamlining key processes and automatically optimising your inventory levels.

Are you interested in learning more about how Unleashed can help improve sustainability in your operations? Follow these steps to start eliminating waste in your business today:

1. Watch a cloud manufacturing software demo. Discover how cloud-based manufacturing software helps you automate key production processes to boost manufacturing sustainability and minimise your business costs.

2. Sign up for a free 14-day trial of Unleashed. Do you prefer a hands-on experience? Peek inside the software and explore the benefits for yourself with a risk-free two-week trial of Unleashed.

3. Read more about manufacturing inventory software. Learn more about the ways cloud manufacturing software can help you eliminate wasteful practices and improve business efficiency.