The sales order process is one of the most vital workflows in any business that sells goods. Get it right and you’ll cut costs and delight customers. Get it wrong and – unfortunately – the opposite tends to apply. So what is sales order processing, how does it work, and why should you optimise it?

What is sales order processing?

Sales order processing, also known as sales order management, is the flow of steps from customer ordering through to product delivery. Sales order processing touches each step of the purchase and order fulfilment process, including quoting, the financial transaction, order picking and logistics.

Ideally a business should run a smooth sales order management process that ensures customer satisfaction, with few errors, fast delivery times and minimal time wasted on admin.

Sales orders vs purchase orders and invoices

Sales order processing, and in particular the phrase ‘sales order’, is not to be confused with purchase orders and invoices:

Sales order vs purchase order

A sales order and purchase order are, in essence, the same thing but going in opposite directions.

A sales order comes from the seller – your business – and is generated to confirm that a sale has been made. It outlines what goods have been sold, their quantities, payment methods, delivery information and so on.

A purchase order goes in the other direction. It comes from the customer and outlines what they wish to purchase. For example, a manufacturer may send a purchase order to their supplier outlining what they require. The supplier would then generate a sales order on the back of that purchase request, once the price has been accepted.

Sales order vs sales invoice

A sales invoice is the final piece of the puzzle, acting as the bill for goods and services. When a price has been agreed and a sales order issued, an invoice can be generated by the supplier and sent to the buyer outlining the agreed payment terms. Whether this is before or after receipt of goods is up to the two parties.

The accounting team of each party records both the sales order and sales invoice to ensure that they match – as part of the reconciliation process.

Sales order processing steps

The basic steps of sales order processing are usually:

- Receive the order

- Generate a sales order

- Picking, sorting and packing

- Shipping

- Invoicing

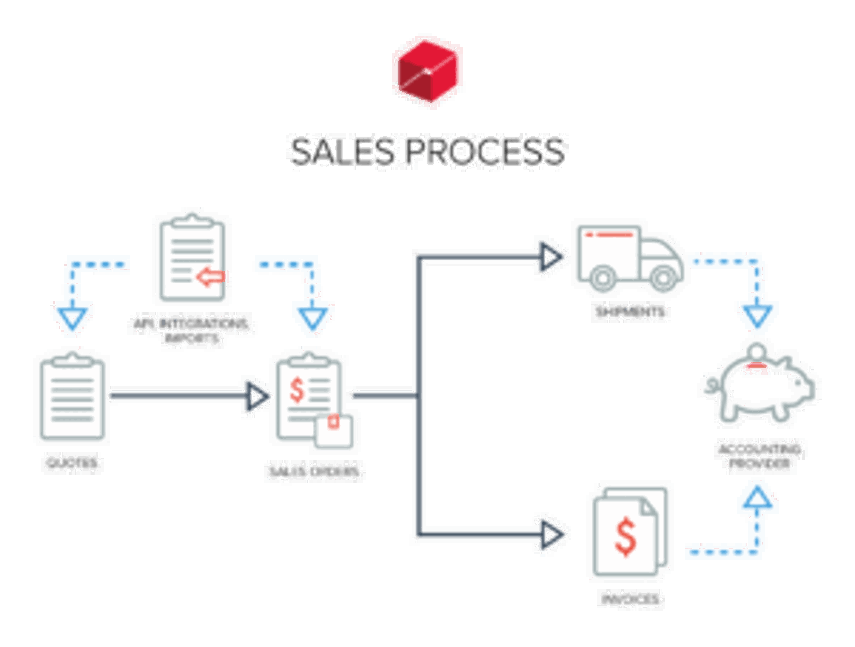

A sales order flowchart gives you a top-down view of each step in your sales order pipeline and can be used to explore inefficiencies in your sales order processes

A sales order flowchart gives you a top-down view of each step in your sales order pipeline and can be used to explore inefficiencies in your sales order processes

Example of a typical sales order process flow

Here we break down the individual steps in a typical sales order process workflow, from receiving an order to invoicing.

Step 1: Receive the order

The first step in any sales order process is order receipt. The customer initiates their purchase order through their platform of choice, whether that’s over the phone, online, or via your mobile app – we’ll talk more about multichannel sales processes below.

Sales orders should include:

- Requested products

- Quantities

- Shipping details

If your company has multiple warehouses or fulfilment centres, shipping details are important – they’ll help you decide which of your warehouses you send the order to.

Step 2: Generate a sales order

For some companies generating a sales order is automatically included in Step 1 – so effectively it’s all one process.

To make this a single step in your sales order process, your stock levels need to be kept up to date and held electronically in a central database that is integrated with your sales ordering system – also known as an order management system (OMS).

When your sales ordering system determines that your company has the right goods in stock, it raises its own sales order and passes the details on to the relevant warehouse managers.

Any company that doesn't use an automated system has to do this manually – in other words, a staff member receives the purchase order, checks stock, then raises a sales order.

Companies that use sales order management software can combine receiving purchase orders with generating their sales order - taking some of the hassle out of the process.

Companies that use sales order management software can combine receiving purchase orders with generating their sales order - taking some of the hassle out of the process.

Step 3: Picking, sorting and packing

When an order has been raised and confirmed, it’s over to the warehouse staff to complete the picking, sorting and packing phases:

- Picking: Warehouse staff pick out the customer’s items so that they can be sorted and delivered. Barcodes and scanners may be utilised here to speed up data entry, allowing warehouse staff to tell the inventory management system that a particular item has been taken off the shelf. Some companies, such as Amazon, are increasingly using robots to automate the picking process.

- Sorting: Picked goods are organised by purchase and delivery location. Picking is often done in batches or zones, where multiple customer orders are picked at the same time from one location in the warehouse. In the sorting phase, these goods are separated into individual customer orders.

- Packing: Finally, orders are packed into appropriate containers, sealed, and labelled for shipping.

What if there isn’t enough stock?

If there isn’t enough stock to fulfil an order, you’ll need to generate a new purchase order for one of your suppliers.

This is where an inventory management system that automatically generates a new purchase order comes in handy. In other words, the system detects that there isn’t enough stock and raises a purchase order with suppliers on its own – updating the computer and customer as required.

- Learn more: What is an Inventory Management System?

Step 4: Shipping

The shipping step is where outbound goods are finally transferred to an approved logistics partner who will then deliver the product to the customer. Depending on what is most cost efficient, or what the customer prefers, purchased goods may be sent out individually or in bulk.

Collecting everything into one shipment can sometimes increase delivery times as it may take longer to pick and sort some goods over others – for instance, when stock isn’t immediately available. On the other hand, sending partial shipments can increase shipping costs and is more complex to manage.

Multiple companies may be involved in this phase. Your business could use a logistics partner to get your goods to a distribution centre, from where a courier delivers the goods to your customer. Alternatively, a single freight company could deliver your goods the whole way.

Shipping is one of the last steps in the sales order process, and for this you may use a logistics partner or freight company

Shipping is one of the last steps in the sales order process, and for this you may use a logistics partner or freight company

Step 5: Invoicing

If payment wasn’t handled at the sales end of the pipeline an invoice will need to be generated so your company receives payment.

A basic system can be used where the invoice is paper-based and mailed out with the package itself. Or the invoice can be generated electronically and emailed to the customer.

Depending on what accounting systems you’re using, you may also be able to use an e-invoice with payment options built in to the invoice itself – like a Pay Now button that is linked to both your accounting platform and the customer’s.

Multichannel sales order management

Any company looking to optimise its sales order management will need to think bigger than traditional sales to a multichannel or – even better – omnichannel strategy.

To optimise for these strategies automation is key, and you’ll be looking to invest in an order and inventory management system that can eliminate time-consuming manual steps like checking stock levels, inputting data into spreadsheets, producing invoices either from scratch or a template, and more.

- Learn more: Order Management Software

When each of these processes is automated they become instant, which means staff can be occupied with more value-adding tasks.

Automating your sales order processes removes time-consuming and tedious tasks for staff - and the risk of human error.

Why multichannel sales order management is important

Most shoppers nowadays – even in the B2B space – want the option to shop online, which means that you’re going to need a multichannel or omnichannel fulfilment strategy if you want to improve your sales order process.

‘Omnichannel’ means that your business sells across multiple platforms and devices, and each of these is integrated into one system. ‘Multichannel’ refers to selling across different platforms, but their systems are separate.

Customers are increasingly looking to make purchases online – which is why a multichannel strategy is so important. The numbers tell the story:

- In the US online shopping made up 14% of all retail sales in Q4 2020, up 11.3% year on year

- There were over 230 million online shoppers in the US in 2021 – again, an increase on years prior

- B2B ecommerce is growing too. It’s expected that 80% of B2B sales will happen digitally by 2025

Benefits of optimising sales order process flows

The sales order process involves a number of very important and sometimes complex steps, and so any degree of optimisation can have huge benefits, including:

- Fewer errors: Automating elements like data entry means there’s less chance of human errors – like typos, or putting decimals in the wrong place. It also reduces the chance that the wrong items will be put in the wrong shipment, or get missed entirely.

- Faster order fulfilment: By streamlining each phase of this process you’re making it faster. That means you’ll pick and ship customer orders more quickly, which cuts costs and delights customers.

- Lower costs: As mentioned, faster fulfilment cuts costs. But it goes beyond that – there’s less chance of errors being made, so fewer costs related to returns and reshipments.

- Complexity is easier to manage: With a streamlined process – especially a digital or automated one – it can be easier to manage more complex orders such as partial shipments. This is because calculations, data entry and order management are done on your behalf. Your teams can get on with what they do best, while the system keeps track of other tasks like sending reminders or shipping out the second or third batch in a partial shipment when stock arrives.

5 ways to optimise sales order management

1. Audit your current system

To optimise your processes you’ll need to start with an audit. This can be a revealing exercise – and you won’t know where you need to go if you don’t know where you are now. If you can’t capture the data you need for this, that is the first point you'll need to address.

Your first step is to map out your current sales order process in a flow chart, describe each step, and ask yourself : Who or what is involved? How long does it take?

From this you can work out the most complex or slowest parts of your pipeline – you’ll look at optimising these first.

Auditing your sales order management process is the first step to improving it.

2. Automate

Automation is about taking tedious and repetitive jobs and letting a computer do them faster and more accurately – so that staff can focus on more meaningful tasks.

For sales order processing, you could think about automating these actions:

- Receiving purchase orders and checking inventory levels

- Raising sales orders if inventory is confirmed

- Sending purchase orders to suppliers if new stock is required

- Raising a sales invoice to be printed or emailed to the customer

- Sending picking requests to the appropriate warehouse manager

- Updating stock levels based on what items are removed from shelves and scanned

- Organising pickups and estimating shipping costs

- Communicating with the customer at key steps in the process, or when there’s a delay

How do you automate these processes?

To manage these steps you’ll need to use order management software that’s integrated with your inventory management system. Between these two systems you can handle the sales process, stock count and supplier requests.

If needed, you can integrate inventory management and order management systems with an enterprise resource planning (ERP) system to connect with more apps, such as those for accounting, sales databases, CMS platforms, and so on.

- Learn more: 5 Perks of Automation for Employees

3. Invest in inventory management software

Inventory management is key to optimising almost the entire first half of the sales order workflow.

If you don’t know what stock you have at any given time, or you can’t update this information in real time, you will always be at risk of stocking out unexpectedly – or overstocking goods that you then can’t sell.

Inventory management software is designed to cover this and more. It allows you to track and manage your stock, and even generate business intelligence reports so you can see what is profitable in your business and what's not.

Inventory management software deals with some of the core processes involved in sales orders, and is therefore an essential part of any sales order software system

Inventory management software deals with some of the core processes involved in sales orders, and is therefore an essential part of any sales order software system

4. Explore demand forecasting

Demand forecasting builds on inventory management by using a range of data to predict future demand. Factors like historical sales data, seasonal factors and your own forecasts all combine to help the system calculate when consumers are going to want particular products, and in what quantity.

From there you’re able to ensure you have stock in the right place, in the right quantity, at the right time – meaning less risk that you’ll either run out of stock due to unexpected demand, or that you’ll order too much stock when demand is due to drop.

- Learn more: Advanced Inventory Manager

5. Learn to manage reverse logistics

When you’ve optimised each element of your sales order process, there’s still one part of your system that’s left – the reverse supply chain.

Reverse logistics is the term for when goods come back up the supply chain, from customer to supplier or manufacturer. Customer returns are a common example, but unsold goods, end-of-life goods, returned rentals and delivery failures may all be reasons for goods to come up the supply chain in the reverse direction.

If your business isn’t ready to process returned goods quickly and efficiently, it may lead to some of the same problems you’ve already worked hard to mitigate – like slow processing, human error, spiralling costs and dissatisfied customers.

Optimise your workflows with sales order processing software

Sales order processing software, also known as order management software, is a cross between a sales database and order control. It can track sales orders in real time to give you maximum visibility, and allows you to manage sales orders based on purchase date, delivery date, warehouse location, current status, and fulfilment capacity.

Unleashed's powerful sales order processing features also enable you to generate purchase orders for suppliers off the back of a sales order for the customer if there isn’t enough stock in-house at the time of purchase. Easily reserve stock for future sales, partial orders or specific sales channels – and receive automated alerts that let you know about overdue orders.

To find out if the Unleashed sales order processing system is right for you, follow these next steps:

1. Watch a sales order processing software demo. Learn how to manage sales orders, track inventory, and report on key business metrics in real time to save you money while boosting efficiency with Unleashed.

2. Sign up for a free 14-day trial. Discover first-hand how Unleashed helps you streamline order management, maximise sales, and improve operational productivity with a risk-free two-week trial.

3. Chat with an expert to assess your needs. Are you ready to take your business to the next step? Book a free chat with one of our in-house experts for an honest discussion about sales order processing workflows.

More posts like this

- 5 Factors that Spell Supply Chain Failure - In a world of increasingly complex supply chains, businesses are increasingly conscious of the need to ensure that they and their suppliers have made ...

- Behemoth Brewing Company Grows Twelvefold with Unleashed Inventory Management Software -Behemoth Brewing Company joined Unleashed when a lack of inventory control started causing serious stock problems. Since adopting Unleashed inventory ...

- Online Order Fulfilment Guide for eCommerce - Minimising wasteful activities and improving online order fulfilment efficiency should be a goal for any product business. This allows you to spend le...