If you’ve ever had inventory sitting in the storeroom or warehouse unused, unsold, and taking up space – you’ve experienced dead stock. It represents lost revenue and increases your holding costs and opportunity costs. Fortunately, efficient dead stock inventory management can help you avoid those losses.

This guide explains all you need to know about dead stock. We’ll cover the definition then break down some effective dead stock analysis, dead stock liquidation, and dead stock accounting strategies. Let’s dive in.

What is dead stock?

Dead stock, also called obsolete inventory, is stock that is unlikely to sell but remains on the shelves of your storage facility. It can appear in the form of raw materials, in-progress inventory, or finished goods. Dead stock often sits, unsold and forgotten, on your back shelves and in the far recesses of your warehouse, losing its value once it has reached the end of its product life cycle.

The dangers of dead stock in business

The main danger of dead stock is that it can lead to an incremental increase of obsolete inventory. This has the potential to create storage and logistic problems that result in increased carrying costs. Dead stock also leads to cash flow problems because any inventory that can’t be sold is an expense to your business and a loss of potential profit.

Each bit of space devoted to dead stock is a lost opportunity. It prevents you from holding more quantities of your top-selling inventory items, resulting in missed revenue opportunities. Dead stock also costs money to keep in storage.

Carrying any quantities of unsellable and obsolete inventory will affect your bottom line. It can reduce your profit margins, tie up your cash flow, and increase your warehouse storage and employee costs. The primary benefits of clearing out your dead stock are that it frees up space and increases your revenue potential.

Dead stock examples

Dead stock can accumulate due to a variety of causes, from technological advancement and consumer attitudes to global events and seasonality of goods. It affects a range of products and production lines across many industries.

Here are some common examples of dead stock:

- Perishable stock that has passed its use-by date, such as fresh produce used in food and beverage production.

- Electronic products that have been superseded by new technologies. Think floppy discs, overhead projectors, and video cassettes (if you’re old enough to remember them!).

- Physical products that have been replaced by digital alternatives such as hard copy telephone books, business catalogues, and encyclopedias.

- Unsustainable or inefficient products and appliances – for example, coal-burning fireplaces and high-energy-using white goods.

- Single-use plasticware, plates, cups, cutlery, straws, containers, and shopping bags that have been phased out for cultural and environmental reasons.

- Party and event items sold for specific occasions, such New Year's merchandise that instantly become dead stock once that date or occasion has passed.

Dead stock: 5 common causes

Dead stock typically occurs when a business is no longer able to sell an item or consume a production material at the same velocity as predicted.

Five common causes of dead stock:

- Inaccurate demand forecasting

- Poor product quality or design

- Excessively long lead times

- Inefficient inventory management

- Decreased customer demand

Let’s look at each of these in more detail,

1. Inaccurate forecasting

Inaccurate forecasting of your consumer demand puts you at risk of excess inventory stock, as it can result in holding items that become obsolete before you can sell them.

Once obsolete, stock can result in additional storage costs for your business. Any time your product reaches the end of its life cycle, it has the potential to become unsaleable, which is why accurate demand forecasting is vital.

To better predict future demand for products, track and analyse historical data using inventory management software. Some tools, such as Unleashed, can even help to automate the forecasting process based on your recorded inventory data for each product.

2. Defective product design or quality

Inferior quality or design occurs when your product fails to meet the expectations of your consumers. This will lead to a rapid decline in product demand, leaving you with dead stock that you can’t sell.

Poor quality can also result from products that have a short life cycle or perishable goods such as food, medicines, and cosmetics.

Better product research, demand forecasting, and quality assurance practices will help you mitigate dead stock losses due to poor quality and design.

3. Inefficient inventory management

Poor inventory management is a significant contributor to dead stock. If you aren’t completely on top of where your goods are located and how well they’re selling, it’s easy to overstock on the wrong inventory.

To counter this challenge, online inventory management provides you with real-time inventory data. It gives you a complete picture of what’s happening in your organisation by recording every transaction, with live tracking of your inventory levels to help prevent surplus stock and avoid the occurrence of obsolete or dead stock.

4. Lengthy lead times

Any inefficiency in your supply chain can lead to long lead times. Long lead times often result in businesses holding safety stock to account for supply disruptions. This can cause an accumulation of excess inventory that never sells.

With more accurate forecasting or by implementing a just-in-time delivery strategy you can streamline your supply chain to reduce lead times and decrease the amount of stock you have on hand. This can prevent the risk of dead stock by improving the accuracy of purchase orders to consumer demand.

5. Decreased demand

Dead stock inventory created by reduced demand for a product is one of the most difficult causes to mitigate.

There are numerous reasons for low demand. It could be due to waning popularity, products being rendered obsolete by newer products, or that your customers simply don’t like the product.

For a low-demand inventory, the best way to minimise your losses is by discounting the price and ridding yourself of the unpopular merchandise as quickly as possible to avoid it becoming dead stock.

Dead stock prevention strategies

Dead stock prevention strategies help you to look at and understand the causes of dead stock in your business. Failure to implement a prevention strategy for dead stock inventory will affect your profitability and increase your storage costs.

Improve demand forecasting

Improving your demand forecasting is the first step to preventing dead stock. You can improve your demand forecasting by analysing historic product data, sales patterns, and market trends.

Optimising your demand forecasting gives you greater inventory control. With inventory software systems you can be better informed to avoid purchasing too much stock or investing in slow-moving products that lead to dead stock.

Streamline stock-keeping units (SKUs)

Streamlining your SKUs is a stock rationalisation process where you measure the profitability of the products you manufacture or stock. Using production, purchase, inventory storage cost metrics, and historical sales data, you can determine if an SKU should be kept, discontinued, or retained with some modifications.

All these factors will assist you in determining whether certain SKUs are helping or harming your business. Streamlining inventory SKUs helps to lower operational costs and mitigate the risk of dead stock.

Optimise order volumes

Consider opting for smaller order quantities or reducing your production runs. This is especially important when dealing with trendy or seasonal items that can experience rapid declines in customer demand.

A just-in-time inventory strategy allows you to order small quantities more frequently, helping to eliminate overproduction or over-ordering. This aids you in avoiding a buildup of unsalable stock that becomes dead stock.

Implement inventory optimisation software

Inventory optimisation software offers your greatest defense against dead inventory stock.

Without optimised inventory management, dead stock can remain in your warehouse, forgotten and taking up valuable space. With inventory management software you can avoid accumulating dead stock in the first place.

Inventory software solutions enable tracking, monitoring, and visibility of your inventory in real time. It supports continuous turnover, preventing stock out, spoilage, and dead stock inventory.

How to sell dead stock: 9 effective liquidation tips

For manufacturers, dead stock accumulates when you’ve produced too many items that didn’t sell as predicted. It also occurs if you overstock raw materials that are perishable or aren’t used in production. This dead stock is much harder to get rid while still recouping some of the purchase price paid.

Retailers have more opportunities to get creative in ways that their customers will see value. Here we look at nine proven methods for liquidating dead retail stock.

1. Bundling

Product bundling means curating complementary products to sell together. Bundling is an effective strategy for clearing dead stock because it taps into the velocity of your best-selling products.

Here are three common tactics you can use to bundle and sell low-demand products inventory:

- Bundle dead stock items with more current products and sell the combination at a discount. Gift bundles are especially popular around holidays and special events.

- Bundle items that are only available when purchased exclusively in a bundle. This is referred to as pure bundling.

- Bundle a mix of products, usually sold separately, and offer the bundle at a discounted price.

Keep learning: Check out comprehensive guide to product bundling for more ideas.

2. Creative merchandising

Get creative with how you present dead stock to potential buyers. Design visually appealing displays in-store and imaginative visuals online to showcase your merchandise.

You can use props, themes, and lighting to arrange your inventory and present it in a more appealing way.

It also pays to understand the flow of customers through your stores and strategically place dead stock in high-traffic areas. For example, display products near the entrance and again near your POS counter.

3. Clearance sales

Clearance sales are an easy way to quickly get rid of any superfluous stock.

A report by McKinsey revealed that 74% of consumers and 87% of Gen Zers are trading down – in other words, looking for cheaper ways to shop.

The clearance sale strategy is simple: a sale of unwanted inventory, sold at heavily reduced prices to clear the inventory from stock. You can take any unsold stock left over after a clearance sale and try to get rid of it by using some of the other tactics listed here.

4. Donations

While clearance sales are great for clearing slow-moving or seasonal inventory, there is a chance that some of this dead stock has value to charity or not-for-profit organisations. By donating last season’s coats or jackets you not only generate community goodwill, but you may also qualify for a tax deduction of the market value after donation.

5. Giveaways

Not all customers will want to pay the retail price for an item they don’t like enough, but when you offer the item for free with the purchase of another, more appealing and higher priced, item then there is a perception of good value for money.

Giveaways, through gifts and discounts, are a great incentive to get customers to buy.

6. Liquidation retailers

If you have large volumes of dead stock to get rid of, liquidation retailers can be a good option. However, liquidators typically buy inventory at severely discounted prices so you might not get the full inventory value.

This strategy will help you clear space in your warehouse, reduce your storage cost, and generate some cash from obsolete stock that already lost most of its value.

7. Marketplaces

Marketplaces such as eBay, Amazon, TradeMe, and Gumtree are great platforms for you to rid your business of any slow-moving or dead stock inventory. The sites allow you to reach many more potential customers, increasing your chance of finding buyers interested in purchasing large amounts of dead stock.

8. Returns

Is it possible to return unmovable inventory to your supplier?

If yes, then don’t hesitate to try this strategy out for yourself.

Supplier returns policies allow selling dead inventory stock back to the vendor. While your business may struggle with shifting this stock, your supplier may be able to move it elsewhere, particularly if it’s still relatively current.

If returns are a viable option, you should also be prepared to make a small loss when sending dead stock back to a supplier.

9. Write-offs

Writing off obsolete inventory reduces the value of your inventory and potentially any taxes payable on the unsold items. A journal entry is created to write off dead stock by debiting the dead stock account and crediting the inventory account for the same amount.

What is dead stock in accounting?

Dead stock inventory accounting is the process of identifying your obsolete inventory and the items that are no longer sellable. It can include damaged goods, leftover seasonal items, or expired raw materials.

Dead stock in accounting tracks and records the cost of your unsold inventory.

To determine your dead stock for accounting purposes, take the following steps:

- Assess the value of the dead stock inventory. Common methods used to determine an appropriate valuation method include the original purchase cost, market value, or net realisable value.

- Create a journal entry to write off the dead stock inventory. Debit the dead stock or obsolete inventory account and credit the same amount into your inventory account.

- Update your financial statements. You can do this by adjusting your balance sheet or income statement to account for your reduced inventory value and to reflect the write-off.

- Maintain detailed records of the inventory write-off. Remember to include any supporting documentation such as valuation calculations, inventory reports, and journal entries.

Calculating the cost of dead stock

A dead stock analysis will identify what dead stock your business is holding and evaluate the cost of that dead stock. You can calculate the value of dead stock by multiplying it by the current price.

To accurately calculate dead stock, you should:

- Determine the timeframe, such as annually or quarterly, for which you are analysing a dead stock.

- Review sales and inventory records to identify all the items and SKUs that have not sold during that period.

- Calculate the total cost of the inventory that has not been sold. Include both the cost of the products themselves along with any shipping, storage, and handling costs to get a true cost of the inventory.

- Calculate the percentage of dad stock inventory by dividing the total cost of unsold inventory by your total inventory value for the period.

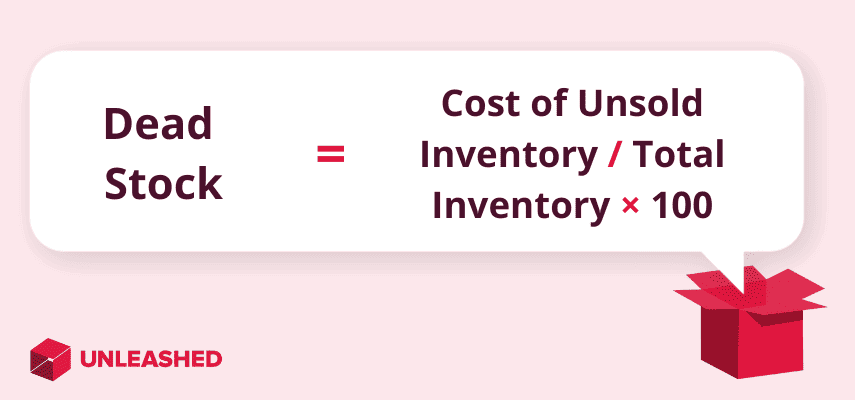

The formula for calculating dead stock inventory is:

Total Cost of Unsold Inventory / Total Inventory for the Period × 100 = Dead Stock

Dead stock inventory management

Dead stock inventory management should be part of your company’s overarching inventory strategy. Inventory software solutions are an integral part of helping businesses to achieve accurate and timely inventory control.

Dead stock analysis

Dead stock analysis is the process of discovering the value and location of your existing dead stock. This is achieved through live tracking and monitoring of inventory levels across the business.

Advanced Inventory Manager (AIM) – the new Unleashed inventory optimisation add-on enables warehouse teams and retailers to spot dead stock immediately and act before it becomes costly.

How to manage dead stock inventory

The best way to manage dead stock inventory is to avoid it in the first place.

Automated online inventory management not only helps you to manage your dead stock inventory but also helps to stop it from accumulating.

Inventory management software manages purchase ordering, tracks orders, and helps to manage returns.

Tracking lets you see where inventory is across your supply chain, and the software reporting and analytics capabilities improve demand forecasting to reduce the risk of acquiring dead stock.